So I have discussed my 2 systems here on various threads for our house in Delaware. I have a 70,000 BTU Ducane propane based furnace, and a 2.5 ton AC system. The old house was one level and the basement, and it was poorly insulated. When I blew in some insulation in the attic, the AC seemed to keep up okay.

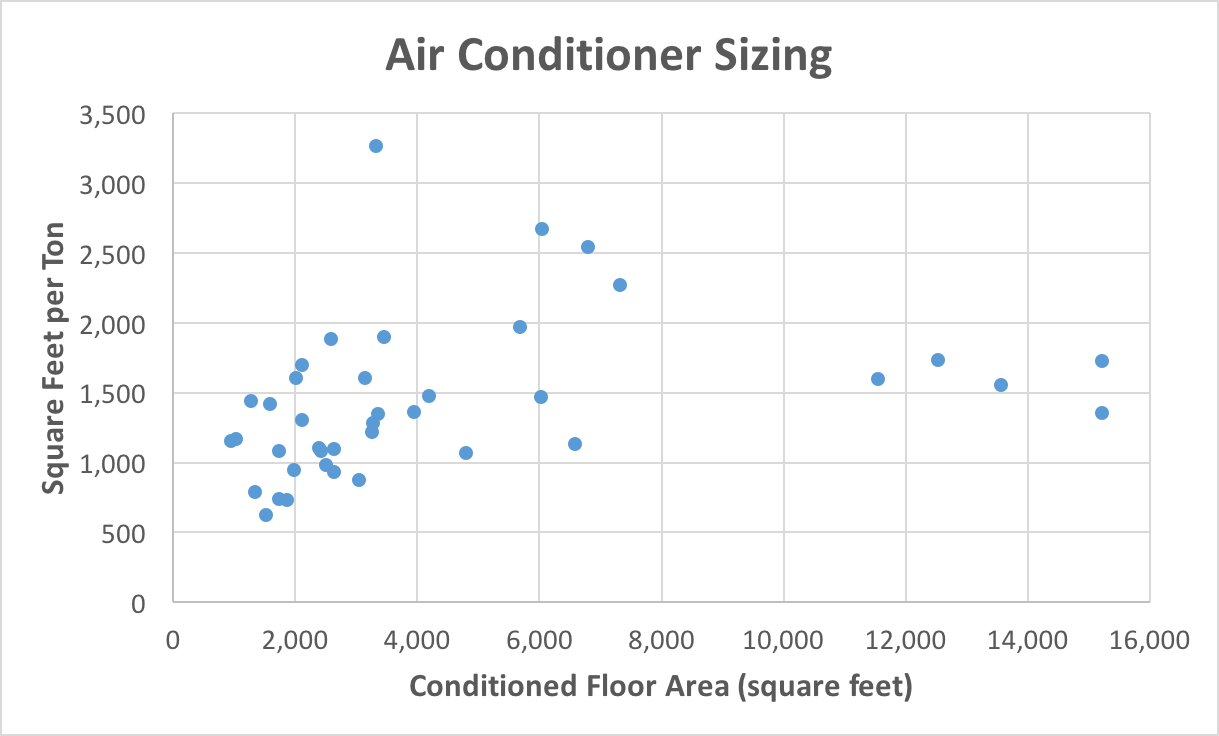

The furnace is probably about 12 years old, and the AC is 8 years old. We have added a 2nd floor, for our master suite, which is about 400sqft, with a Mitsubishi ducted system, so that they can hit the main bedroom area, and then a duct to hit the bathroom. The HVAC guy was making a push to upgrade the existing system for the main level, and the basement. The main level expanded by about 150sqft, and the ceiling height is going to be 9ft. We are getting all new windows, 6inch depth on most of the walls, and all new insulation. The house will be alot tighter, than the old house. The new house will be about 1500sqft on the main level, and an additional 400 sqft in the basement. The HVAC guy was pushing a new system to replace the old system...but I really don't think I need it right away. He was pushing a larget Mitzu system, to drive both zones. I'm sure it would be more efficient, and I would save a few bucks on my montlhly bills. I said that I would like to just do the one mitzu system, and to improve the ducting in the main level of the house, since everything is down to the stud right now. The HVAC guy was stating 500sqft per ton, and I seem to recall on this forum that that is not the case, especially when everything is new. I did ask for the ManualJ results...but I may not get to see them. I did a rough estimate using a site that I found, and I think that I will be fine. I do like the idea of getting away from the propane based system..but we have so many expenses right now, and I just don't want to take that expense during the renovation

The furnace is probably about 12 years old, and the AC is 8 years old. We have added a 2nd floor, for our master suite, which is about 400sqft, with a Mitsubishi ducted system, so that they can hit the main bedroom area, and then a duct to hit the bathroom. The HVAC guy was making a push to upgrade the existing system for the main level, and the basement. The main level expanded by about 150sqft, and the ceiling height is going to be 9ft. We are getting all new windows, 6inch depth on most of the walls, and all new insulation. The house will be alot tighter, than the old house. The new house will be about 1500sqft on the main level, and an additional 400 sqft in the basement. The HVAC guy was pushing a new system to replace the old system...but I really don't think I need it right away. He was pushing a larget Mitzu system, to drive both zones. I'm sure it would be more efficient, and I would save a few bucks on my montlhly bills. I said that I would like to just do the one mitzu system, and to improve the ducting in the main level of the house, since everything is down to the stud right now. The HVAC guy was stating 500sqft per ton, and I seem to recall on this forum that that is not the case, especially when everything is new. I did ask for the ManualJ results...but I may not get to see them. I did a rough estimate using a site that I found, and I think that I will be fine. I do like the idea of getting away from the propane based system..but we have so many expenses right now, and I just don't want to take that expense during the renovation