Elton Noway

Member

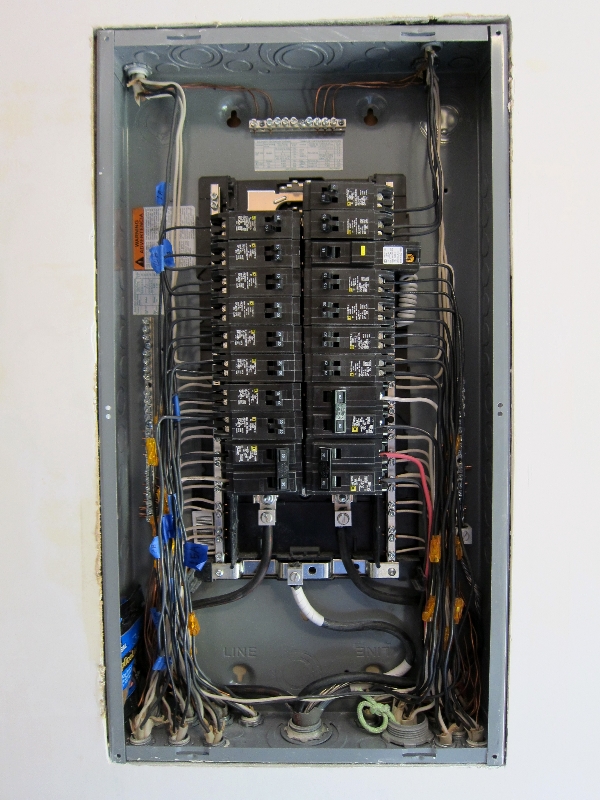

Yep thanks... I marked the wall a couple of days ago to indicate maximum for the highest breaker. Guess it looks like the new panel will be going in upside down.There is no minimum height for a panel, just maximum height of breaker (6'7"). So you could mount new panel lower and upside-down is fine for most - especially a main lug without main breaker. What is on the other side of the wall? As is a laundry room you have the luxury of being able to remove some drywall. If you also remove from adjacent stud bays you should be able to reroute cables and minimize splices.

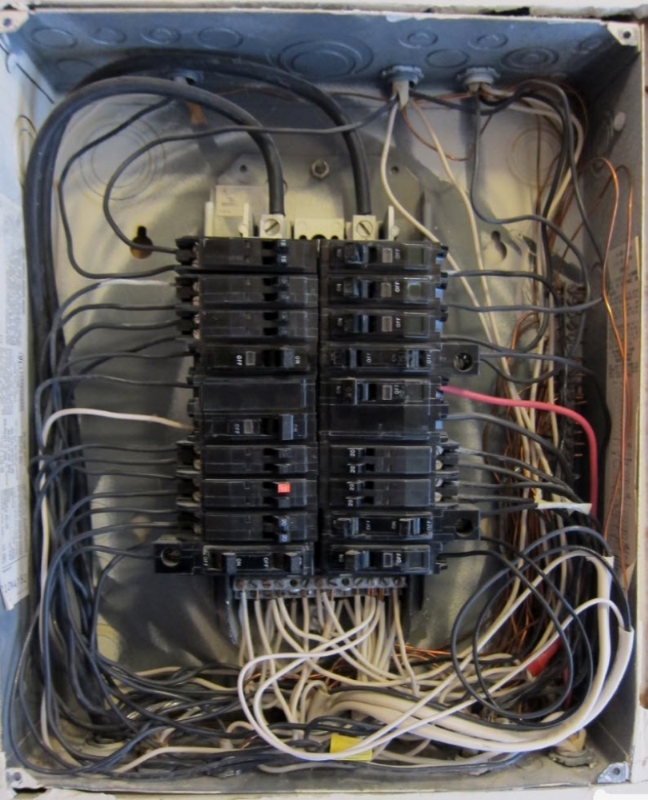

Funny you should mention removing drywall to simplify the project... I did that very thing 13 years ago. As a result, it's also the very thing that's giving me headaches. We had a unused wall off the kitchen I built a coffee bar with wine cooler. (espresso machine for me...wine cooler for the wife) Anyway... I wanted the wine cooler to be flush with the front of the cabinets I was going to install to give it a custom look. To pull it off the plan was to remove a section of drywall behind the wine cooler location so it could slide the cooler back another 4 inches into the recess created by the cavity between the studs. I knew the sub panel wiring might be a problem. As feared... some of the wires feeding up to the sub panel were in the way. With the drywall out I preceded to disconnect the circuits that were in the way and pulled the offending wires down into the crawl space, cut new holes in the floor and rerouted them up and around the cavity and back into the box. Some wires ended up being pretty short so placed those breakers in the spaces nearest the bottom of the panel. As it was I had to splice two circuits . Hence there is no slack left to work with. Also... if you look at the coffee bar you will see and outlet and a wall switch just below the location of the panel which is why I could only move it down an inch and a half if I'm lucky.

Guess I'll be cutting some drywall tonight.