Geobrick

Member

[Update- This turned out not to be a Union leak but there's still some good information on that topic here. By post 14 I realized the leak wasn't at the union and in post 53 I isolated the leak to the service riser pipe buried about 20" underground. Enjoy the process!]

Need some help on the best method and tool for tightening (or loosening for removal and replacement) a Union fitting on a natural gas line especially if it's in a tight location (I'll add a picture to show the obstacles).

Background:

The gas company recently walked through our neighborhood looking for gas leaks (mostly looking for leaks on their side of the meter). They found a leak by my service entrance and isolated it to a line going to our pool equipment. (They turned off all the equipment valves, pressured the line it and watching for a pressure drop. The pressure did drop pretty fast so they turned of the valve feeding that line and red tagged it. It was beyond their scope to find and fix the actual leak (which is understandable).

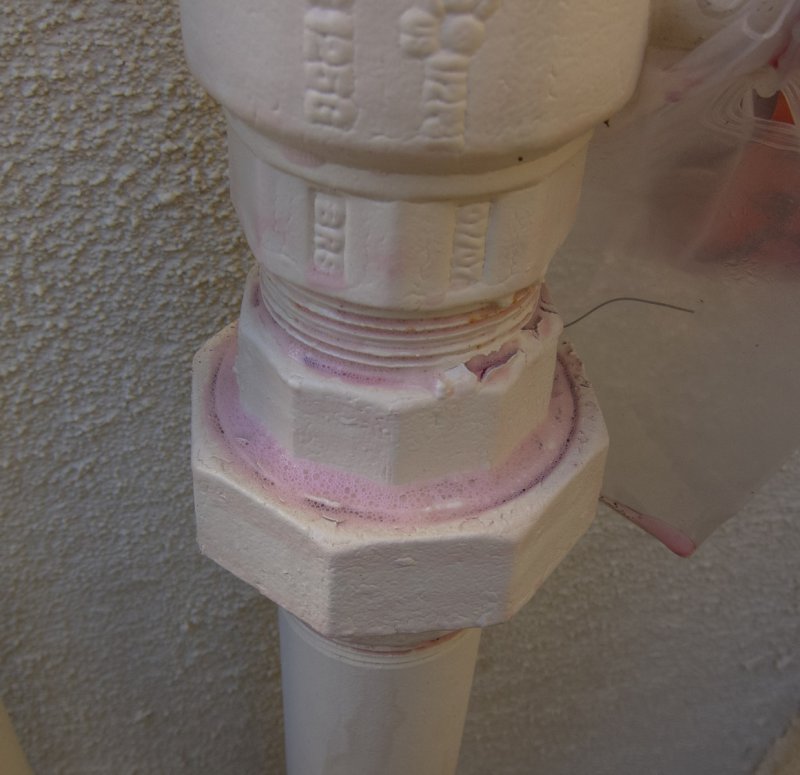

I decided to attempt finding the leak myself. I put a pressure test gage on the line and pressurized the line to 8lbs (all equipment valves off along with the valve feeding the line). I used some gas leak detector spray on all the visible fitting connections (above ground) and saw some bubbling on the Union. The pressure was down to 6lbs in a half hour and down to 3 within 2 hours.

Here are some photos. The first being the union on the pressurized line (8lbs) I was checking and the second picture is another line that wasn't suspected but also shows bubbling. That line is currently in use and only has the normal operating pressure (post meter). The first union is about 13 years old and the 2nd is 21 years old (as old as the house). Should I try tightening them first or would you just replace the unions?

Need some help on the best method and tool for tightening (or loosening for removal and replacement) a Union fitting on a natural gas line especially if it's in a tight location (I'll add a picture to show the obstacles).

Background:

The gas company recently walked through our neighborhood looking for gas leaks (mostly looking for leaks on their side of the meter). They found a leak by my service entrance and isolated it to a line going to our pool equipment. (They turned off all the equipment valves, pressured the line it and watching for a pressure drop. The pressure did drop pretty fast so they turned of the valve feeding that line and red tagged it. It was beyond their scope to find and fix the actual leak (which is understandable).

I decided to attempt finding the leak myself. I put a pressure test gage on the line and pressurized the line to 8lbs (all equipment valves off along with the valve feeding the line). I used some gas leak detector spray on all the visible fitting connections (above ground) and saw some bubbling on the Union. The pressure was down to 6lbs in a half hour and down to 3 within 2 hours.

Here are some photos. The first being the union on the pressurized line (8lbs) I was checking and the second picture is another line that wasn't suspected but also shows bubbling. That line is currently in use and only has the normal operating pressure (post meter). The first union is about 13 years old and the 2nd is 21 years old (as old as the house). Should I try tightening them first or would you just replace the unions?

Last edited: