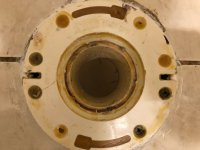

I just installed a new Ultramax II and noticed some very slight wobble while caulking (~1/32 of an inch in the very front). Is this something the caulking will fix as it cures or do I need to remove the toilet, get a new wax seal, and start over? Thanks for the advice and this great forum!

P.S. Lesson learned, the "Danco Perfect Seal" wax ring does NOT seem to work with a 1/2" high flange on the Ultramax II :-( . I may have just be doing something wrong, but the toilet wouldn't even make contact with the floor. I threw it out and used a normal wax ring instead.

P.S. Lesson learned, the "Danco Perfect Seal" wax ring does NOT seem to work with a 1/2" high flange on the Ultramax II :-( . I may have just be doing something wrong, but the toilet wouldn't even make contact with the floor. I threw it out and used a normal wax ring instead.

Last edited: