Hi all,

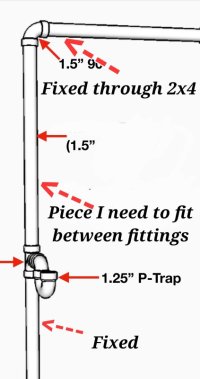

I'm currently redoing some bathroom plumbing. I've finished with the drain pipes and I'm currently on the venting part. It already has venting in place that looks good so I'm going to use that. My question/problem is that I need to fit the 1.5" pvc pipe between my drain pipe to the pre-existing vent and they're both fixed or have no really movement to them. Picture attached is a rough example.

Is there aome technique to get the piece that I'm not seeing? I know they have to bottom out so I can't just cut them a little bit shorter right?

If there is no real technique to get the piece in then is my next step gluing two smaller pieces on the fittings and then using a slip coupling?

Thanks!

I'm currently redoing some bathroom plumbing. I've finished with the drain pipes and I'm currently on the venting part. It already has venting in place that looks good so I'm going to use that. My question/problem is that I need to fit the 1.5" pvc pipe between my drain pipe to the pre-existing vent and they're both fixed or have no really movement to them. Picture attached is a rough example.

Is there aome technique to get the piece that I'm not seeing? I know they have to bottom out so I can't just cut them a little bit shorter right?

If there is no real technique to get the piece in then is my next step gluing two smaller pieces on the fittings and then using a slip coupling?

Thanks!