MTcummins

In the Trades

Normally, this would be pretty simple, but my system is not that simple, so here goes. I have an open radiant floor heat system, so its combined with my DHW. Yes, I'm well aware of everyone's concerns about legionaires, etc, and have addressed them all with redundancy in both temperature and circulation, had it approved by one of the strictest plumbing authorities in the country, etc... so lets talk about adding a DWHR system to the mix.

I currently have my system set up where in the heating season, all the cold makeup water from any draw of hot water flushes through the entire floor system, but cold water draws go straight to the fixtures. In summer, I switch 2 valves, and all the water in the house (with the exception of kitchen cold line) goes through the flooring first to further eliminate any chance of stagnation, as well as give a slight cooling effect (giant heat sink for floors), and preheat my DHW with unwanted waste heat from the house.

Now I'd like to add the DWHR system. I'm thinking it would be nice if I could minimize the dumping of cold water into my warm floors in heating season as much as possible, while retaining the water movement, cooling effects, etc of the current system, and adding the benefits of waste water heat recovery from any sources, but mostly showers. So I'm thinking of a somewhat complicated system, and wanted to see if I'm missing anything as far as how this might go wrong. I'm not concerned about selling the house or next owners etc, and I'll have things well labeled just in case (and so I don't have to head scratch again every season change about how to switch it over.

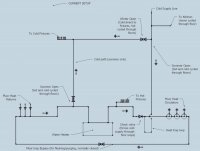

Anyway, the first image is my current setup. Note that I drew it spread out to make things clearer. In reality, all the valves etc are within a couple feet of each other, so no significant stagnation zones... There are some other details excluded, etc, but I think this covers all the most relevant items. Also note that I have a home run manifold system with every fixture having its own line all the way from the manifolds.

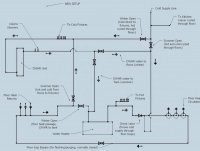

Second image is what I'm thinking of doing. All of the drains in the house except my old (still occasionally active) laundry room and a rarely used basement tub go into this drain stack. Note the shower cold supplies are moved to after the DWHR as well, rest of cold supplies remain as they were. That image is pretty hard to follow with all the valves, notes, etc...

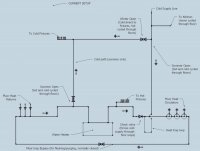

so third image shows only the closed valves on each mode separately to try to show the water pathways for each mode.

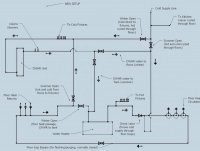

4th is same as 3rd, but I drew in water pathways in blue lines for cold water, orange for DWHR tempered water, and red for fully heated water. Hopefully this all makes sense.

I think I've thought through every possibility of how the system could short circuit somewhere etc, but if anyone sees anything I might have missed, would greatly appreciate the input.

Also, any specific experiences with different manufacturers of DWHR units? I see several that seem to be out of production, some that seem to be only in Canada (I'm in PA), etc. I've been looking at the Power-Pipe (seems best design to me, but not sure), and Thermopipe (mostly because I found a 42" for under $500 shipped, way cheaper than the Power-Pipe models, so ROI would be much faster). I can only fit a 42-45" without totally shoehorning it in (then maybe a 48, maybe), so seems like the couple hundred bucks price difference is more substantial than any modest gains I might be able to get with a different model. But I'm open to suggestions.

I know Dana used to chime in about these a lot. I'd love your (and everyone else's) input!

I currently have my system set up where in the heating season, all the cold makeup water from any draw of hot water flushes through the entire floor system, but cold water draws go straight to the fixtures. In summer, I switch 2 valves, and all the water in the house (with the exception of kitchen cold line) goes through the flooring first to further eliminate any chance of stagnation, as well as give a slight cooling effect (giant heat sink for floors), and preheat my DHW with unwanted waste heat from the house.

Now I'd like to add the DWHR system. I'm thinking it would be nice if I could minimize the dumping of cold water into my warm floors in heating season as much as possible, while retaining the water movement, cooling effects, etc of the current system, and adding the benefits of waste water heat recovery from any sources, but mostly showers. So I'm thinking of a somewhat complicated system, and wanted to see if I'm missing anything as far as how this might go wrong. I'm not concerned about selling the house or next owners etc, and I'll have things well labeled just in case (and so I don't have to head scratch again every season change about how to switch it over.

Anyway, the first image is my current setup. Note that I drew it spread out to make things clearer. In reality, all the valves etc are within a couple feet of each other, so no significant stagnation zones... There are some other details excluded, etc, but I think this covers all the most relevant items. Also note that I have a home run manifold system with every fixture having its own line all the way from the manifolds.

Second image is what I'm thinking of doing. All of the drains in the house except my old (still occasionally active) laundry room and a rarely used basement tub go into this drain stack. Note the shower cold supplies are moved to after the DWHR as well, rest of cold supplies remain as they were. That image is pretty hard to follow with all the valves, notes, etc...

so third image shows only the closed valves on each mode separately to try to show the water pathways for each mode.

4th is same as 3rd, but I drew in water pathways in blue lines for cold water, orange for DWHR tempered water, and red for fully heated water. Hopefully this all makes sense.

I think I've thought through every possibility of how the system could short circuit somewhere etc, but if anyone sees anything I might have missed, would greatly appreciate the input.

Also, any specific experiences with different manufacturers of DWHR units? I see several that seem to be out of production, some that seem to be only in Canada (I'm in PA), etc. I've been looking at the Power-Pipe (seems best design to me, but not sure), and Thermopipe (mostly because I found a 42" for under $500 shipped, way cheaper than the Power-Pipe models, so ROI would be much faster). I can only fit a 42-45" without totally shoehorning it in (then maybe a 48, maybe), so seems like the couple hundred bucks price difference is more substantial than any modest gains I might be able to get with a different model. But I'm open to suggestions.

I know Dana used to chime in about these a lot. I'd love your (and everyone else's) input!

Last edited: