Ian Simpson

New Member

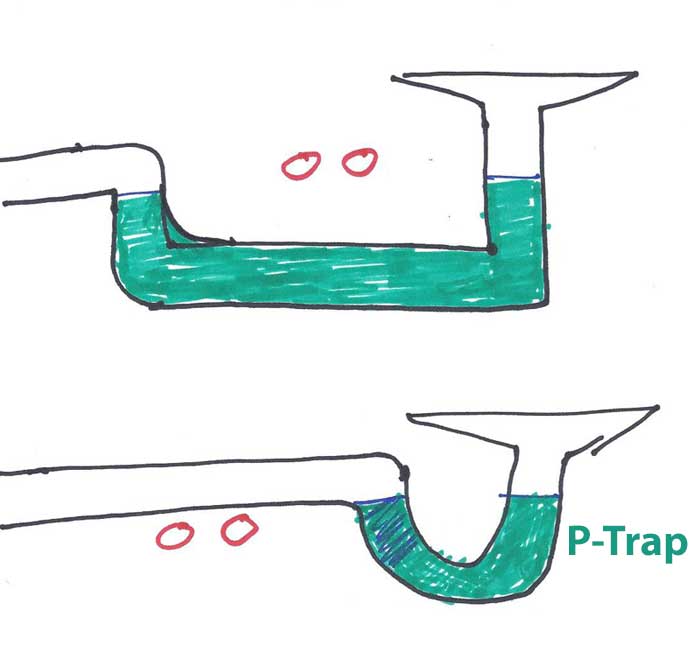

This is my first plumbing project and I’m not sure what’s going wrong. I had to make an extended p trap to go under some water supply lines but now that I’ve got it all together it seems to be draining way to slow. Could the length of the p trap be causing the slow drain rate? I did a bunch a research and couldn’t find anything that said this wouldn’t work. Any other reasons why this would be draining slow? See the attached images.