Ceramicbrad56

New Member

Hi. I recently installed a Fleck 2510SXT greensand filter and noted that the pressure during backwash is too low at the location of the filter to be effective(less than 20 psi ). The system it is installed (in house) has the following from input to output:

1. submersible pump new, 1.5 hp flow rate of > 25 gpm tested by running two sill cocks simultaneously.

1(a). 1" pvc lines in house, 1-1/4" pipe in well.

2.bladder tank(86 gallon ) -(equivalent to a 220 gallon tank) pressure set to 39 psi

3.pressure switch 40/60

4. pressure gauge

5. relief valve(75 psi)

6.60 mesh filter

7.chlorine injection port

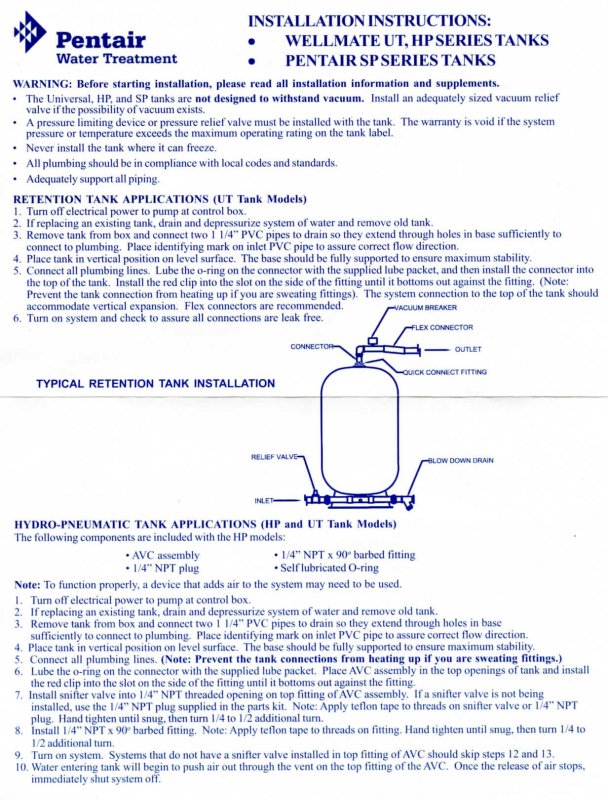

8. 120 gallon retention tank(pentair ut-120 set up as a retention tank with vacuum breaker and output on top and no avc assembly)

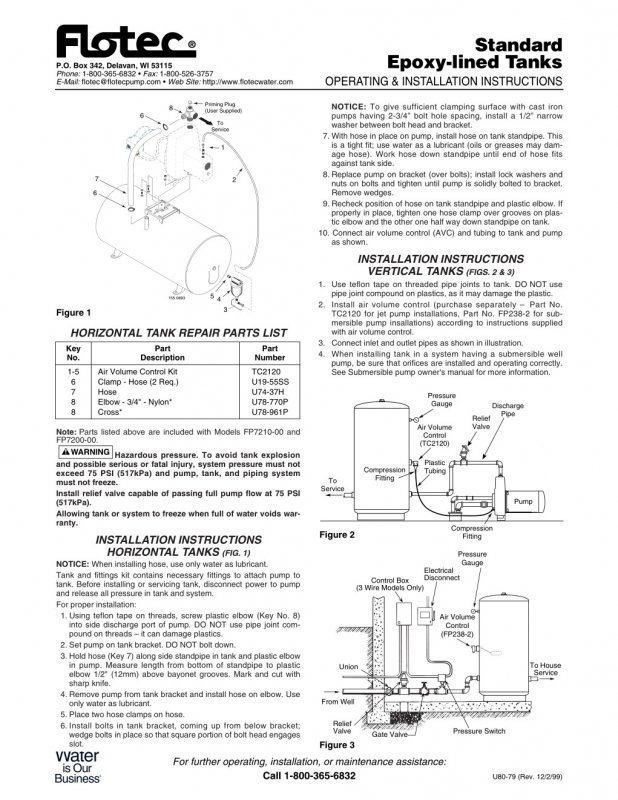

9. flotec FP7250 120 gallon air over water pressure tank with air volume control for submersible pump installed

10. pressure gauge

11. fleck greensand filter

12. whole house filter(big blue)

13. house water input

OK, the system works, no pump switch chattering or leaks but the main issue is the pressure gauge at #4(above) reads 20 to 30 psi higher than the one at #10(above). So, when the fleck backflushes, the water pressure goes from 60 to 10 psi within 10 minutes, while the pressure gauge #4 still above 40 psi and so pump not start to re-pressurize house. Once the pump does kick in at 39 psi, and pump up pressure to 60 psi(on gauge #4) and turn off, the house pressure will slowly go up to 40 or 50 psi(taking10 minutes or so). So my question is what are my options here? (put the pressure switch at #9-the Flotec?)

1. submersible pump new, 1.5 hp flow rate of > 25 gpm tested by running two sill cocks simultaneously.

1(a). 1" pvc lines in house, 1-1/4" pipe in well.

2.bladder tank(86 gallon ) -(equivalent to a 220 gallon tank) pressure set to 39 psi

3.pressure switch 40/60

4. pressure gauge

5. relief valve(75 psi)

6.60 mesh filter

7.chlorine injection port

8. 120 gallon retention tank(pentair ut-120 set up as a retention tank with vacuum breaker and output on top and no avc assembly)

9. flotec FP7250 120 gallon air over water pressure tank with air volume control for submersible pump installed

10. pressure gauge

11. fleck greensand filter

12. whole house filter(big blue)

13. house water input

OK, the system works, no pump switch chattering or leaks but the main issue is the pressure gauge at #4(above) reads 20 to 30 psi higher than the one at #10(above). So, when the fleck backflushes, the water pressure goes from 60 to 10 psi within 10 minutes, while the pressure gauge #4 still above 40 psi and so pump not start to re-pressurize house. Once the pump does kick in at 39 psi, and pump up pressure to 60 psi(on gauge #4) and turn off, the house pressure will slowly go up to 40 or 50 psi(taking10 minutes or so). So my question is what are my options here? (put the pressure switch at #9-the Flotec?)

Last edited: