Reading all these replies to the original question, I see that some corrosion and galvanic cell information is really needed.

Galvanic corrosion put simply is a battery with a completed circuit allowing current to flow around the completed circuit. An unconnected battery sitting on a table is half of a complete circuit. The battery is the corrosion part. Electrochemically dissimilar materials are connected thru an electrolyte. The equivalent in a fluid system (in this case, a water heater and plumbing), are the dissimilar metals used and the water as an electrolyte. A battery sitting on the table with no connections (no completed circuit) will not react inside. The dissimilar metals in the water heater and plumbing will not corrode rapidly either if they are not electrically connected. Another way that to slow corrosion is to increase the resistance of the electrolyte. There are two ways to increase the electrolyte resistance. One is to make the conductor "longer" by separating the dissimilar materials by putting more distance between them. In a battery, for example, you want just the opposite so that corrosion can take place rapidly. The dissimilar materials are only separated by a thin electrolyte film. The other way to increase the electrolyte resistance is to make the water a poorer electrolyte, making it less reactive with the materials and less able to carry a current between the two materials. A dead car battery has almost pure water in it with high resistance as opposed to a fully charged battery that has very acidic water in it that is highly reactive and conductive. So this is why soft water is more corrosive in water systems. It is more reactive and a better electrolyte. In a home water system, the softness or reactivity of the water coming to your house may not be something that you can control. But if you use if a water softener, you can dial in how soft (reactive) you make your water.

So to summarize how to reduce corrosion in the water heater and system. Use less reactive metals, separate them as best you can in the electrolyte (water), use less reactive water (hard, less acidic water is better), and above all, try not to connect the dissimilar metals to complete the circuit (don't let them touch or be connected).

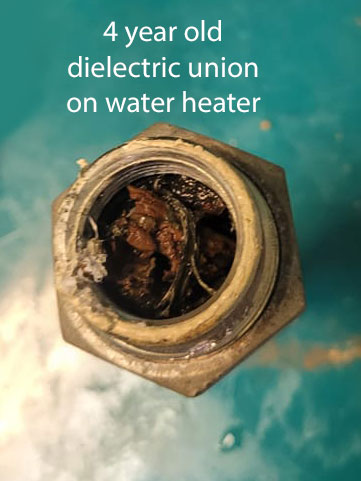

So to correct a misconception, the plated steel nipples supplied on many domestic water heaters are absolutely NOT dielectric. They may have plastic inserts for masking some of its surface area or holding heat trap devices. But they are not dielectric couplings. Dielectric means NON-conductive. A dielectric coupling is made to connect between two plumbing pipes without letting the two touch electrically. The use of a dielectric coupling is like disconnecting a battery. To prove to yourself that these nipples are not dielectric, get an ohm meter. Measure the resistance between the cold water inlet nipple and the hot water outlet nipple. A dead short (less than an ohm) means there is no dielectric coupling at all. In contrast, a dielectric coupling will have more than 20 Mohms measured between its ends.