Jeff Davis

Member

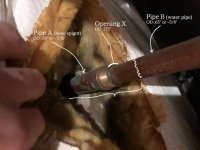

So I think that I may have a cracked spigot pipe that leaks within my foundation wall. I've suspected this since November, when I shut off my hose bibs, but I never got around to diving into the project this winter. I'm guessing that the majority of the leaking water flows out the spigot-pipe penetration on the exterior of the house (and under the fiber-cement siding). FYI, I have yet to turn on the hose bib this spring.

Attached are some pictures.

Symptoms:

1. The lawn and flower bed, located near the spigot, were wet all last year (lots of mushrooms and fungus were growing in that area as well), before I turned off the spigot for the winter

2. From visible water stains, it looks like some water was leaking through the spigot penetration onto the foundation wall insulation inside the house

Since it looks to me like the pipe is soldered instead of screwed in, how can I check to be sure it is actually cracked without cutting the pipe?

Thanks!

-Jeff

Attached are some pictures.

Symptoms:

1. The lawn and flower bed, located near the spigot, were wet all last year (lots of mushrooms and fungus were growing in that area as well), before I turned off the spigot for the winter

2. From visible water stains, it looks like some water was leaking through the spigot penetration onto the foundation wall insulation inside the house

Since it looks to me like the pipe is soldered instead of screwed in, how can I check to be sure it is actually cracked without cutting the pipe?

Thanks!

-Jeff