arcman49

New Member

I would like to know why my pump is drawing beyond the specified amps 7 GPM (start up) to 6 GPM (draw down).

(Sorry if this is wordy but I figured I should include as much info as I can up front. )

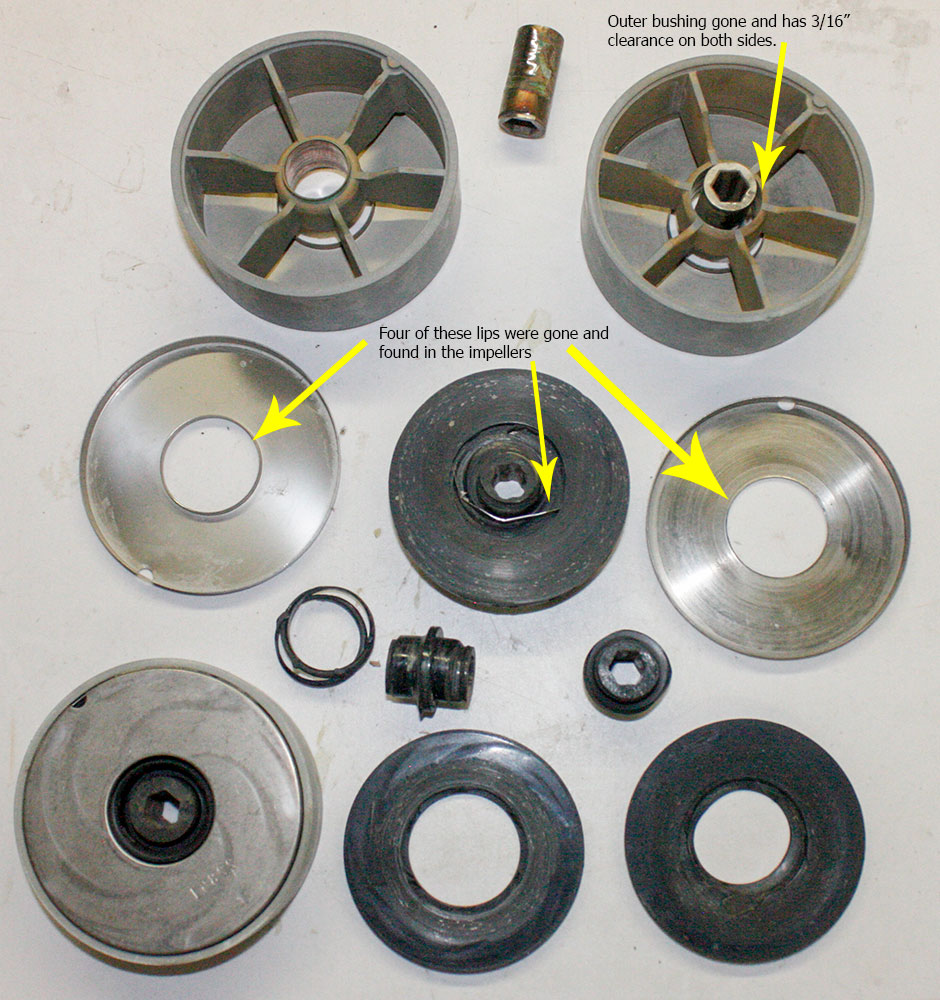

Our well showed symptoms of a leaking check valve so I pulled the pump. It was cycling a few times an hour when there was no demand. Upon inspection, a piece of a stage had broken off and lodged in the pumps check valve. The pump was on its last leg with a 1/4" of clearance on the top bushing and the top few impellers were destroyed. The other check valves on the pipe were in bad shape too, one stuck open.

Our well is 25 years old, 399 ft deep, 3 gpm and the pump is hung on 1" schedule 80 pvc at 340 ft. The well drillers report showed static water level at 110 ft., Gravel & Clay down to 56 ft., Hard Pan 56-57 ft, and then Limestone down to 399. When we pulled the pump, after 80 feet or so there was a considerable amount of rust attached to the pipe and the torque arrestors. You could wipe if off the pipe by hand. Almost looked like it was floating and attached itself to the pipe as it was pulled up.

The old (original) pump was a Burks 7SN21a. 3/4 hp, 21 stage 5 gpm pump. (info here: https://quicksilver.epa.gov/work/05/506823.pdf - page 13) There has been only two of us in the house the entire time. We've never showed signs of running out of water.

I decided on a Sta-Rite replacement pump and after a couple of emails and phone calls to them they helped narrow my application down to a S5P4HS07221-02. Specs similar to the Burks. 5gpm, 3/4 hp, 18 (or 19?) stage. Before installing, I checked the static level in the well and it was at 64ft. Could this be because of the large amount of rain here lately in southeast Wisconsin?

We installed new check valves, pipe and stainless couplers but not the 12ga. wire. It looked fine.

Years ago I installed a 22" whole house filter because of the water being cloudy and seeing a fine grey sediment in the toilet tanks. That filter is right off the well inlet to the house but there is also a 'T' it shares for a spigot. The filter has a valve on the inlet so I can block it from the pump and run water directly from the pump through the spigot.

We started the pump and immediately it had the usual fine grey silt but it also included fine pieces of what again looked like rust, small enough to get through the pumps screen. It pumped at 7 gpm for about 45 minutes when the neighbor (who helped me on the install) mentioned we should check the current flow of the pump. The manufactuers specs show continuous 5 amps and the service limit at 6.1. Using a RMS clamp on ammeter it showed 6.5 amps. Somewhat worried, we shut it off for the day and checked it the next day.

Immediately it showed similar current, 6.3 - 6.5. We ran it for over an hour and it stayed at those numbers. We stopped the pump briefly and restarted and the current went to 6.8-6.9 amps.

We checked the resistance of the pump and wire and it was within spec, Voltage at the top of the well was 237.

I called Sta-Rite and they said this would reduce the life of the motor and recommended using a flow restrictor at the pump. We tried restricting the flow to 4 gpm via the spigot and it didn't reduce the current draw. Could it be the sand and silt is causing the increase in amperage?

Any comments on this would be appreciated.

Now the second issue. After pouring a gallon of bleach down the well and running the hose back into it for 30 minutes, the water now looks awful. I suppose that's from washing the walls of the iron pipe. It's brown in color and after filling a five gallon bucket you can't see your fingers three inches deep. We ran if for over an hour and the rust subsided but it's still cloudy, with some grey silt and fine black sand. Maybe half a teaspoon in five gallons. I assume this is what wore out the original pump.

Will this eventually clean up or am I a candidate for a sand screen?

Thanks for your time.

Lee Hagen

Delafield,WI

(Sorry if this is wordy but I figured I should include as much info as I can up front. )

Our well showed symptoms of a leaking check valve so I pulled the pump. It was cycling a few times an hour when there was no demand. Upon inspection, a piece of a stage had broken off and lodged in the pumps check valve. The pump was on its last leg with a 1/4" of clearance on the top bushing and the top few impellers were destroyed. The other check valves on the pipe were in bad shape too, one stuck open.

Our well is 25 years old, 399 ft deep, 3 gpm and the pump is hung on 1" schedule 80 pvc at 340 ft. The well drillers report showed static water level at 110 ft., Gravel & Clay down to 56 ft., Hard Pan 56-57 ft, and then Limestone down to 399. When we pulled the pump, after 80 feet or so there was a considerable amount of rust attached to the pipe and the torque arrestors. You could wipe if off the pipe by hand. Almost looked like it was floating and attached itself to the pipe as it was pulled up.

The old (original) pump was a Burks 7SN21a. 3/4 hp, 21 stage 5 gpm pump. (info here: https://quicksilver.epa.gov/work/05/506823.pdf - page 13) There has been only two of us in the house the entire time. We've never showed signs of running out of water.

I decided on a Sta-Rite replacement pump and after a couple of emails and phone calls to them they helped narrow my application down to a S5P4HS07221-02. Specs similar to the Burks. 5gpm, 3/4 hp, 18 (or 19?) stage. Before installing, I checked the static level in the well and it was at 64ft. Could this be because of the large amount of rain here lately in southeast Wisconsin?

We installed new check valves, pipe and stainless couplers but not the 12ga. wire. It looked fine.

Years ago I installed a 22" whole house filter because of the water being cloudy and seeing a fine grey sediment in the toilet tanks. That filter is right off the well inlet to the house but there is also a 'T' it shares for a spigot. The filter has a valve on the inlet so I can block it from the pump and run water directly from the pump through the spigot.

We started the pump and immediately it had the usual fine grey silt but it also included fine pieces of what again looked like rust, small enough to get through the pumps screen. It pumped at 7 gpm for about 45 minutes when the neighbor (who helped me on the install) mentioned we should check the current flow of the pump. The manufactuers specs show continuous 5 amps and the service limit at 6.1. Using a RMS clamp on ammeter it showed 6.5 amps. Somewhat worried, we shut it off for the day and checked it the next day.

Immediately it showed similar current, 6.3 - 6.5. We ran it for over an hour and it stayed at those numbers. We stopped the pump briefly and restarted and the current went to 6.8-6.9 amps.

We checked the resistance of the pump and wire and it was within spec, Voltage at the top of the well was 237.

I called Sta-Rite and they said this would reduce the life of the motor and recommended using a flow restrictor at the pump. We tried restricting the flow to 4 gpm via the spigot and it didn't reduce the current draw. Could it be the sand and silt is causing the increase in amperage?

Any comments on this would be appreciated.

Now the second issue. After pouring a gallon of bleach down the well and running the hose back into it for 30 minutes, the water now looks awful. I suppose that's from washing the walls of the iron pipe. It's brown in color and after filling a five gallon bucket you can't see your fingers three inches deep. We ran if for over an hour and the rust subsided but it's still cloudy, with some grey silt and fine black sand. Maybe half a teaspoon in five gallons. I assume this is what wore out the original pump.

Will this eventually clean up or am I a candidate for a sand screen?

Thanks for your time.

Lee Hagen

Delafield,WI

Last edited: