Lordoftheflies

Active Member

Ok I set the bathtub in some sandmix. I was too freaked out about the time and getting everything right since I literally had one shot at doing it.

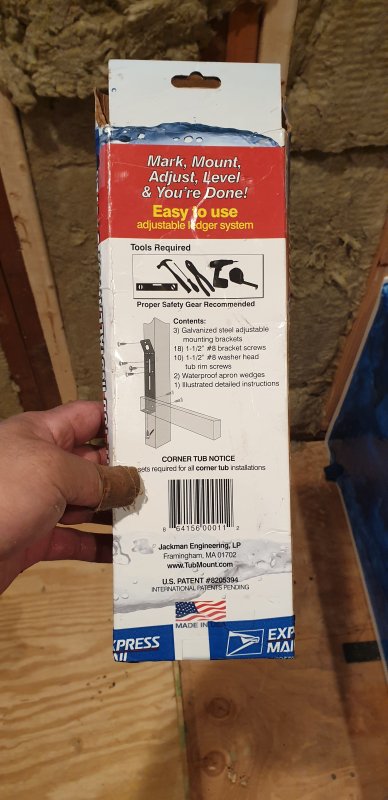

For the ledger boards the instructions for the tub were not 100% clear....but it basically said I needed ledger boards all around. Given that I had to cut out part of the subfloor (not all of it since I nothing to nail into if I had done that) I ended up finding this product on the interwebs. I wonder what you pros think about it. I'll tell you it sure made life easy for me to be able to dry fit, level the tub with shims on the front apron, and then apply a thick bead of silicone caulk to all 3 walls.

The crazy thing about the Tub Mount system is that they don't even process online payments. I had to find their phone number and call them up...and then they didn't even take payment. They sent the product and asked me to send them a check! Talk about the honor system! I could probably help them out on the technical side in getting that up and running....

It's pretty cool - you get these steel straps which you bend a 90 around the 2x4. One screw goes on the bottom, 2 screws on the side of the 2x4.....Then you use one of their washer head screws in the slot. You bend the top of the strap away from the stud to allow you to use an additional slot with a screwdriver to raise the tub. You tap the bent tab to lower the tub. And the first step is to make sure you level the apron.

Here I decided not to drill into the lip of the tap and instead used some large washers and the screws the Tub Mount system came with. I suppose I could just pre-drill a hole and use just the screws and then dab each one with silicone. Any opinions? The way I have it now I'll have to notch out the kerdi board ever so slightly at each washer location.

Before I got the tub mount I was failing miserably at trying to level the tub as you can see by the holes.

For the ledger boards the instructions for the tub were not 100% clear....but it basically said I needed ledger boards all around. Given that I had to cut out part of the subfloor (not all of it since I nothing to nail into if I had done that) I ended up finding this product on the interwebs. I wonder what you pros think about it. I'll tell you it sure made life easy for me to be able to dry fit, level the tub with shims on the front apron, and then apply a thick bead of silicone caulk to all 3 walls.

The crazy thing about the Tub Mount system is that they don't even process online payments. I had to find their phone number and call them up...and then they didn't even take payment. They sent the product and asked me to send them a check! Talk about the honor system! I could probably help them out on the technical side in getting that up and running....

It's pretty cool - you get these steel straps which you bend a 90 around the 2x4. One screw goes on the bottom, 2 screws on the side of the 2x4.....Then you use one of their washer head screws in the slot. You bend the top of the strap away from the stud to allow you to use an additional slot with a screwdriver to raise the tub. You tap the bent tab to lower the tub. And the first step is to make sure you level the apron.

Here I decided not to drill into the lip of the tap and instead used some large washers and the screws the Tub Mount system came with. I suppose I could just pre-drill a hole and use just the screws and then dab each one with silicone. Any opinions? The way I have it now I'll have to notch out the kerdi board ever so slightly at each washer location.

Before I got the tub mount I was failing miserably at trying to level the tub as you can see by the holes.