Hi all,

I'm about to set a new toilet on a new soil pipe that I recently installed.

I installed my soil pipe about a foot higher than the subfloor so that I could later trim it flush after the finished floor was installed. Last night I cut the soil pipe flush with the finished floor.

Now I'm ready to install the toilet flange. In preparation - since I'm not a pro, and I want to do it right - I did some reading and found a couple of instances where individuals were not able to get their closet flange to insert all the way into their soil pipe. I assumed that this was due to inadequate preparation with primer and cement leading to the interference fit providing too much resistance. But I also saw a video where the plumber stated that he cuts the soil pipe about 1/2" below the finished floor so that he can fully insert the closet flange, because otherwise the flange wants to sit a bit higher than the soil pipe.

This morning I did a test fit with an extra closet flange on a short section of 4" pipe to see if I could get the flange to insert all the way into the pipe. I carefully prepared the pipe and flange with primer and cement and was able to insert the fitting easily with just hand/arm force, but for good measure, I also stood on it to make sure it was as fully inserted as possible.

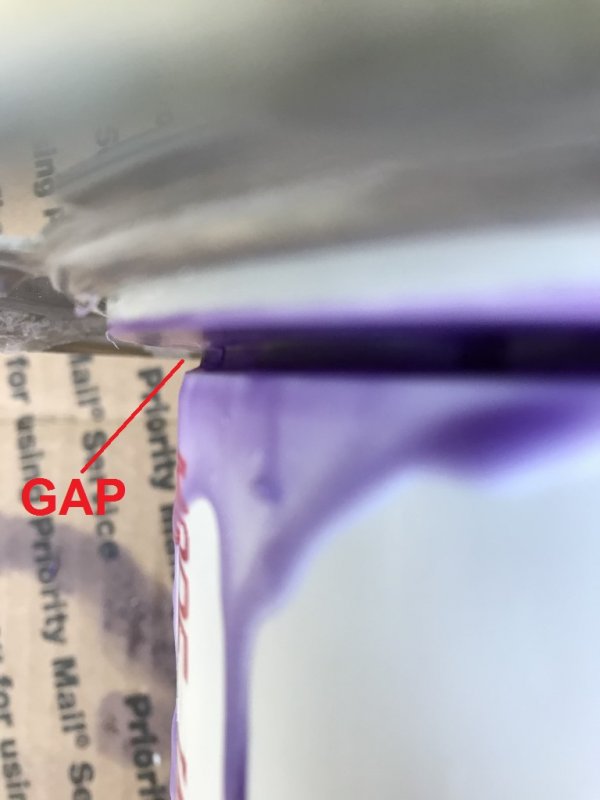

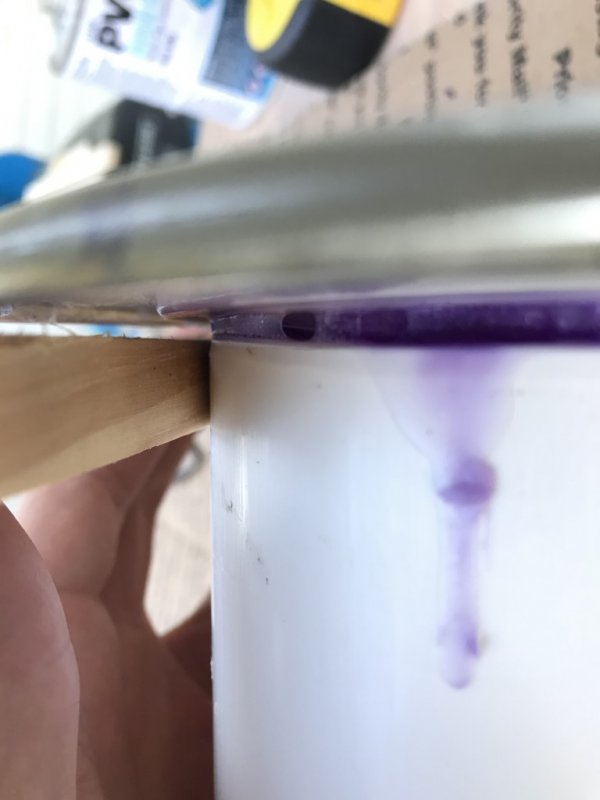

What I found was that the flange sits about 1/8" proud of the pipe. This would cause the flange to sit proud of the finished floor, with a gap between the floor and the stainless ring. In one of the attached photos, I am holding a piece of wood flush with the soil pipe to indicate the finished floor and you can see the gap.

Have any of you run into this issue before?

The simple solution would be for me to get an appropriate tool to cut about 1/4" to 1/2" of the soil pipe so that it sits shy of the finished floor. Are there any other solutions?

Perhaps the specific closet flange that I purchased has a design defect? It is designed for 3" hub or 4" inside - maybe the hub connection works fine but there is a problem when used with 4" inside connections? Here is the one I purchased:

https://www.supplyhouse.com/Sioux-C...ide-Open-Flange-w-Stainless-Steel-Swivel-Ring

Thanks for reading!

I'm about to set a new toilet on a new soil pipe that I recently installed.

I installed my soil pipe about a foot higher than the subfloor so that I could later trim it flush after the finished floor was installed. Last night I cut the soil pipe flush with the finished floor.

Now I'm ready to install the toilet flange. In preparation - since I'm not a pro, and I want to do it right - I did some reading and found a couple of instances where individuals were not able to get their closet flange to insert all the way into their soil pipe. I assumed that this was due to inadequate preparation with primer and cement leading to the interference fit providing too much resistance. But I also saw a video where the plumber stated that he cuts the soil pipe about 1/2" below the finished floor so that he can fully insert the closet flange, because otherwise the flange wants to sit a bit higher than the soil pipe.

This morning I did a test fit with an extra closet flange on a short section of 4" pipe to see if I could get the flange to insert all the way into the pipe. I carefully prepared the pipe and flange with primer and cement and was able to insert the fitting easily with just hand/arm force, but for good measure, I also stood on it to make sure it was as fully inserted as possible.

What I found was that the flange sits about 1/8" proud of the pipe. This would cause the flange to sit proud of the finished floor, with a gap between the floor and the stainless ring. In one of the attached photos, I am holding a piece of wood flush with the soil pipe to indicate the finished floor and you can see the gap.

Have any of you run into this issue before?

The simple solution would be for me to get an appropriate tool to cut about 1/4" to 1/2" of the soil pipe so that it sits shy of the finished floor. Are there any other solutions?

Perhaps the specific closet flange that I purchased has a design defect? It is designed for 3" hub or 4" inside - maybe the hub connection works fine but there is a problem when used with 4" inside connections? Here is the one I purchased:

https://www.supplyhouse.com/Sioux-C...ide-Open-Flange-w-Stainless-Steel-Swivel-Ring

Thanks for reading!