So I installed a softener and carbon tanks, both with the Fleck 5800SXT. Install seemed simple enough, although when I went to do initial settings the water from the carbon tank was coming out with a lot of force from the discharge hose and my basement drain couldn't keep up. I'm having that drain snaked tomorrow as it sounds like there is an obstruction there.

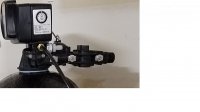

In the meantime, I put both tanks in bypass and unplugged them. That was on Tuesday or Weds this week. Today, one of the little silver brackets on the bypass at the back of the 5800 on the carbon tank popped off and water was shooting across the room in every direction.

I have the mess cleaned up and I have since re-tightened these metal brackets. Did I just not push these on fully and tighten them adequately? I don't see how I could have messed up the bypass install, as the arrows show the flow on them. I didn't think there would be that much force with the water simply going through bypass. Any advice? My wife fully thinks I'm an idiot at this point and should have had the local Culligan guy put a tank in.

In the meantime, I put both tanks in bypass and unplugged them. That was on Tuesday or Weds this week. Today, one of the little silver brackets on the bypass at the back of the 5800 on the carbon tank popped off and water was shooting across the room in every direction.

I have the mess cleaned up and I have since re-tightened these metal brackets. Did I just not push these on fully and tighten them adequately? I don't see how I could have messed up the bypass install, as the arrows show the flow on them. I didn't think there would be that much force with the water simply going through bypass. Any advice? My wife fully thinks I'm an idiot at this point and should have had the local Culligan guy put a tank in.