Hi all. New to messing with boilers and I am piecing an old baseboard system, to a newer tankless boiler and I read that you can remove zone valves and control the zones with circulators. Please, dont try to talk me out of this route because I have already replumbed my system taking out the old zone valves. My question is this.

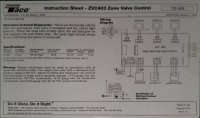

I already have a Taco zvc403 zone valve controller and I would like to try to employ this to control my zone circulators. I understand how relays work for the most part and know just enough to fry some circuits, but I would like to avoid that if possible. I watched a video on wiring a circulator to the taco, which uses the onboarding n/o com n/c connection but that only sends power to the circulator and then that makes the power constant? I want to use the zvc to turn the circulator on for the zone demand as needed.

Am I stuck to order up a new controller designed for controlling zone circulators as the main way to control a zone vs a zone valve?

By the way, I have a Navien NHB 110 boiler with p/s manifold installed. The main circulator on the manifold is wired direct to the boiler slot on the boiler. There is a second 2a slot for another circulator and a 3rd slot for a dhw circulator. I dont believe with the zvc installed, that I need to use these extra slots for anything, especially the domestic hot water slot. Even if I could somehow use the 2nd circulator slot, I now have 3 circulators, which is why I prefer to use the zvc if I can for my application. I included a wiring schematic for my zvc to help. Thanks for any help you can give me.

I already have a Taco zvc403 zone valve controller and I would like to try to employ this to control my zone circulators. I understand how relays work for the most part and know just enough to fry some circuits, but I would like to avoid that if possible. I watched a video on wiring a circulator to the taco, which uses the onboarding n/o com n/c connection but that only sends power to the circulator and then that makes the power constant? I want to use the zvc to turn the circulator on for the zone demand as needed.

Am I stuck to order up a new controller designed for controlling zone circulators as the main way to control a zone vs a zone valve?

By the way, I have a Navien NHB 110 boiler with p/s manifold installed. The main circulator on the manifold is wired direct to the boiler slot on the boiler. There is a second 2a slot for another circulator and a 3rd slot for a dhw circulator. I dont believe with the zvc installed, that I need to use these extra slots for anything, especially the domestic hot water slot. Even if I could somehow use the 2nd circulator slot, I now have 3 circulators, which is why I prefer to use the zvc if I can for my application. I included a wiring schematic for my zvc to help. Thanks for any help you can give me.