PunkEngineer

New Member

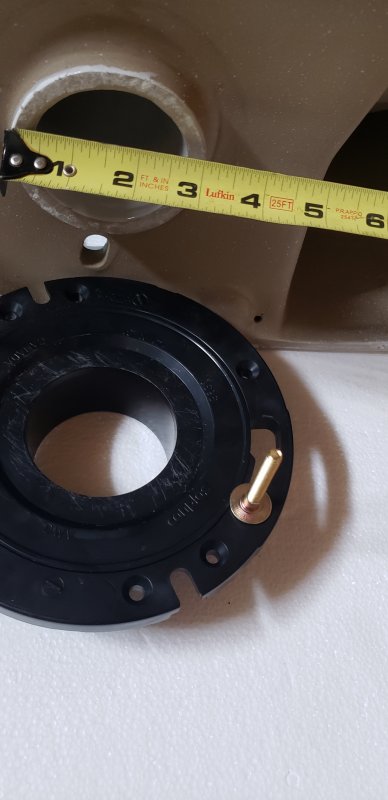

Hi, I have a problem with my toilet flange installation. The problem is that I have a normal 3 inches ABS pipe that it is cut flush to the Polish concrete floor. So I had to buy a toilet flange the fits inside the 3" inside diameter. But this toilet flange has a inside diameter of 2.5". My toilet hole (also flanged see picture) has a 3" outside diameter that does fit inside the ABS flange. So it leaves a gap between the toilet and the ABS flange. It would result in my toilet not laying on the concrete floor but floating at 0.25". Should I use a grinder to cut a little bit the ceramic flange on the toilet. Or only use a classic copper flange and only count on the wax ring to seal this?