JMak00

New Member

But, of course, mine is unique...

TL/DR - Kitchen drains slowly; Section of cast iron that goes into slab under home is filled with gunk. Get a plumber to power snake/jet? Or try Bio-Clean first for a week to see if there's improvement?

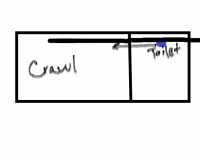

Split-level home with a crawlspace under the kitchen and front entryway. Kitchen sink drains into a single pvc pipe that connects to the laundry drain at a t where the drain pipe then is cast iron leading to the back wall of the crawlspace and I presume under or through the slab for the lower-level of the home.

I can do dishes for about 15-20 minutes and then water backs all the up to the the sink. Will drain very slowly, but drain. Ran a load of laundry and one first rinse cycle, backed up and out the washer overflow.

Multiple attempts at Drano and boiling water flush as well as vinegar and baker soda mix with no improvement.

Several months ago I took out the 20ft of cast iron piping and power washed the gunk out of it. Nice and clean when I put it back in. The part I could not get was the section of pipe that goes into the wall. Put it back together and no leaks and water flowed fine...until this week.

Today I went back into the crawlspace and took apart the cast iron thinking I'd clean it, again, but the sections I removed before are still clean...the piece that is sticking out of the wall is all gunked up, though. My hand-held snake could push into and through that section but couldn't get it past about 8'. Just not stiff enough to push through.

So, took a long rod and started shoving it through the gunk and pulling out what I could and put it all back together...But, I had leaks (doesn't help that I stripped two bands - one on two separate couplings ) and as I let water in to test for leaks I could hear the water backing up inside the pipe.

) and as I let water in to test for leaks I could hear the water backing up inside the pipe.

So...I think it's time to get a plumber out here to snake that section of pipe that goes into the slab. I was able to pull out a lot of gelontinous gunk (and therein saw minced up onions and other food particles so a new disposable is likely needed) going about 3-4 ft in, but, I think when I ran cold water down the drain to test for leaks all that gunk solidified or least balled up, again stopping up the drain.

Now, I did have a local drain cleaning service come out yesterday to inspect and the best they would do for me was give me quotes for re-piping...dafuq? When I asked about snaking the pipe or jetting it, the service dude said he was concerned about damaging the cast iron. Does that sound right?

Lastly, I did add 3 pints of water and 3 scoops of bio-clean into the drain at the sink (3 pints because it's such a long run to where the stoppage is). I figure I'd try that for a few days and see what happens...

Approach:

Use bio-clean for 3 days to see if there's any change to drainage.

Contact multiple local plumbers to inquire about power-snaking the section of pipe going to the wall.

Starting planning to replace the sections of cast iron in the crawlspace with PVC.

The section of pipe that cost into the wall is also cast and it goes into a much wider length of cast that's in the wall. In other words, it looks like someone had foregone ripping out the original section of cast iron that goes into the wall and instead shoved a 2" section right through it. Weird stuff.

TL/DR - Kitchen drains slowly; Section of cast iron that goes into slab under home is filled with gunk. Get a plumber to power snake/jet? Or try Bio-Clean first for a week to see if there's improvement?

Split-level home with a crawlspace under the kitchen and front entryway. Kitchen sink drains into a single pvc pipe that connects to the laundry drain at a t where the drain pipe then is cast iron leading to the back wall of the crawlspace and I presume under or through the slab for the lower-level of the home.

I can do dishes for about 15-20 minutes and then water backs all the up to the the sink. Will drain very slowly, but drain. Ran a load of laundry and one first rinse cycle, backed up and out the washer overflow.

Multiple attempts at Drano and boiling water flush as well as vinegar and baker soda mix with no improvement.

Several months ago I took out the 20ft of cast iron piping and power washed the gunk out of it. Nice and clean when I put it back in. The part I could not get was the section of pipe that goes into the wall. Put it back together and no leaks and water flowed fine...until this week.

Today I went back into the crawlspace and took apart the cast iron thinking I'd clean it, again, but the sections I removed before are still clean...the piece that is sticking out of the wall is all gunked up, though. My hand-held snake could push into and through that section but couldn't get it past about 8'. Just not stiff enough to push through.

So, took a long rod and started shoving it through the gunk and pulling out what I could and put it all back together...But, I had leaks (doesn't help that I stripped two bands - one on two separate couplings

So...I think it's time to get a plumber out here to snake that section of pipe that goes into the slab. I was able to pull out a lot of gelontinous gunk (and therein saw minced up onions and other food particles so a new disposable is likely needed) going about 3-4 ft in, but, I think when I ran cold water down the drain to test for leaks all that gunk solidified or least balled up, again stopping up the drain.

Now, I did have a local drain cleaning service come out yesterday to inspect and the best they would do for me was give me quotes for re-piping...dafuq? When I asked about snaking the pipe or jetting it, the service dude said he was concerned about damaging the cast iron. Does that sound right?

Lastly, I did add 3 pints of water and 3 scoops of bio-clean into the drain at the sink (3 pints because it's such a long run to where the stoppage is). I figure I'd try that for a few days and see what happens...

Approach:

Use bio-clean for 3 days to see if there's any change to drainage.

Contact multiple local plumbers to inquire about power-snaking the section of pipe going to the wall.

Starting planning to replace the sections of cast iron in the crawlspace with PVC.

The section of pipe that cost into the wall is also cast and it goes into a much wider length of cast that's in the wall. In other words, it looks like someone had foregone ripping out the original section of cast iron that goes into the wall and instead shoved a 2" section right through it. Weird stuff.