Hi All,

I am trying to sort out and clean up a well water system on a house I just purchased in Maine. I literally can't trust a thing as everything the previous owner did seemed based upon cheapest/easiest version he could possibly figure out. Also, I was going to hire a water professional, but after 4 different companies came through with 4 wildly differing proposals I decided to tackle the project myself to make sure I get the exact system I want. I am an architect and sometimes builder, so I do have lots of experience with building and renovating and plumbing and wiring.

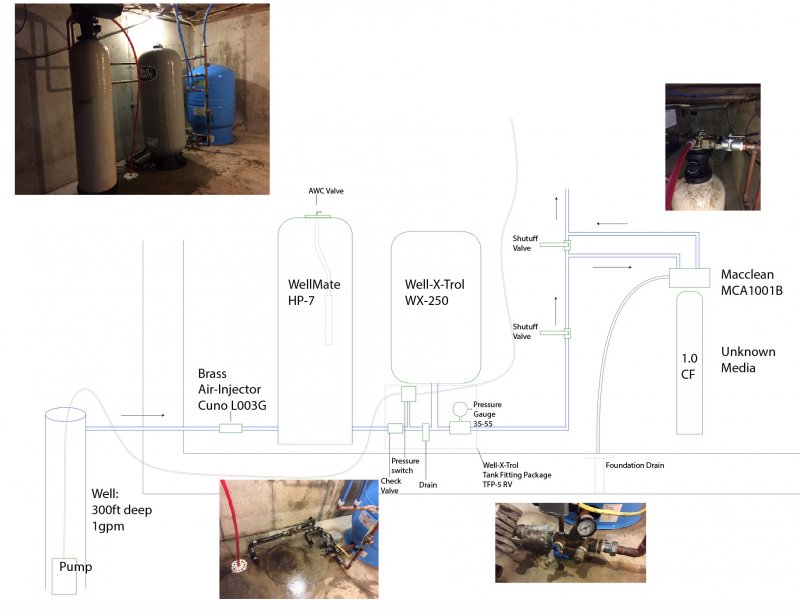

Although my test results directly from the well have not come in, I do have comprehensive results from the tap that say elevated Iron and Manganese as well as a slightly elevated level of Arsenic . Attached is a diagram of my current system:

As the system currently sits, the water was coming from the well, running through a hydrocharger device, then into the WellMate HP-7, that was waterlogged, then going through what I think is a check-valve and pressure switch (35-55) with an Amtrol tank Tee'd off from the line, then onto a MacClean head on a 1.0 CF tank. I am not exactly sure of the media in the tank. They might have put greensand in it. I think it was originally an aqua-pure birm filter.

My main goals currently are to properly oxidize the water so that the ArsenicIII can flip to ArsenicV, and to filter out the iron and manganese.

So, step one was to make sure the water is being oxidized. I cleaned out the WellMate tank and soaked the AWC valve in CLR. Although I think I have it working again, I may pick up a new AWC valve just to be sure. I am then rerouting the piping in order to have better access to the hydrocharger for proper adjustment.

I contacted Pentair yesterday, the maker of the WellMate, and they said that the HP-7 with a functioning AWC should be the only pressure tank in the system as it will allow it to vent more air/gasses if used alone. Simply cutting off the Well-X-Trol from the system. (Small household with two people and two bathrooms)

So, finally the question. What do people think of this idea? Having just the WellMate and cutting off the Amtrol? Should there be any additional devices in the system? Like a check-valve before the WellMate? Ultimately, starting at the wall where the water comes into the basement, what should the exact sequence of parts be in order to have good pressure and oxidize the water for later treatment?

Should I not spend a nickel on this setup and take a different route?

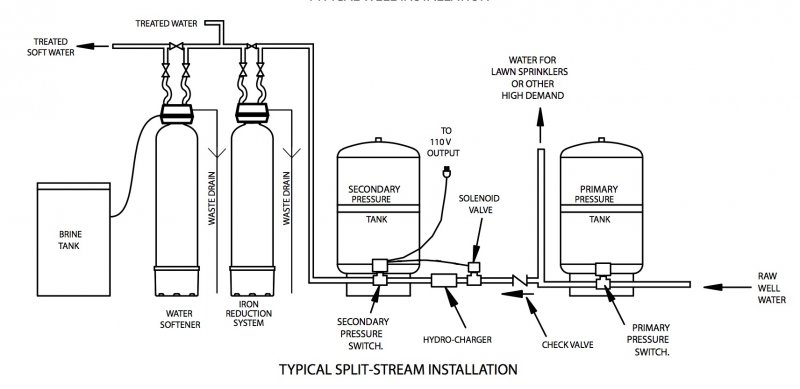

What about this split tank setup? Seems really interesting, except for the part with the additional solenoid valve costing $250.

Some additional details:

Submersible well pump

7GPM flow rate

I am trying to sort out and clean up a well water system on a house I just purchased in Maine. I literally can't trust a thing as everything the previous owner did seemed based upon cheapest/easiest version he could possibly figure out. Also, I was going to hire a water professional, but after 4 different companies came through with 4 wildly differing proposals I decided to tackle the project myself to make sure I get the exact system I want. I am an architect and sometimes builder, so I do have lots of experience with building and renovating and plumbing and wiring.

Although my test results directly from the well have not come in, I do have comprehensive results from the tap that say elevated Iron and Manganese as well as a slightly elevated level of Arsenic . Attached is a diagram of my current system:

As the system currently sits, the water was coming from the well, running through a hydrocharger device, then into the WellMate HP-7, that was waterlogged, then going through what I think is a check-valve and pressure switch (35-55) with an Amtrol tank Tee'd off from the line, then onto a MacClean head on a 1.0 CF tank. I am not exactly sure of the media in the tank. They might have put greensand in it. I think it was originally an aqua-pure birm filter.

My main goals currently are to properly oxidize the water so that the ArsenicIII can flip to ArsenicV, and to filter out the iron and manganese.

So, step one was to make sure the water is being oxidized. I cleaned out the WellMate tank and soaked the AWC valve in CLR. Although I think I have it working again, I may pick up a new AWC valve just to be sure. I am then rerouting the piping in order to have better access to the hydrocharger for proper adjustment.

I contacted Pentair yesterday, the maker of the WellMate, and they said that the HP-7 with a functioning AWC should be the only pressure tank in the system as it will allow it to vent more air/gasses if used alone. Simply cutting off the Well-X-Trol from the system. (Small household with two people and two bathrooms)

So, finally the question. What do people think of this idea? Having just the WellMate and cutting off the Amtrol? Should there be any additional devices in the system? Like a check-valve before the WellMate? Ultimately, starting at the wall where the water comes into the basement, what should the exact sequence of parts be in order to have good pressure and oxidize the water for later treatment?

Should I not spend a nickel on this setup and take a different route?

What about this split tank setup? Seems really interesting, except for the part with the additional solenoid valve costing $250.

Some additional details:

Submersible well pump

7GPM flow rate