Yukoner777

Member

Hi guys

My boiler guy has kind of abandoned me, as he took on a bunch of commercial work. I'm hoping you can help me out with an issue that seems to crop up every fall.

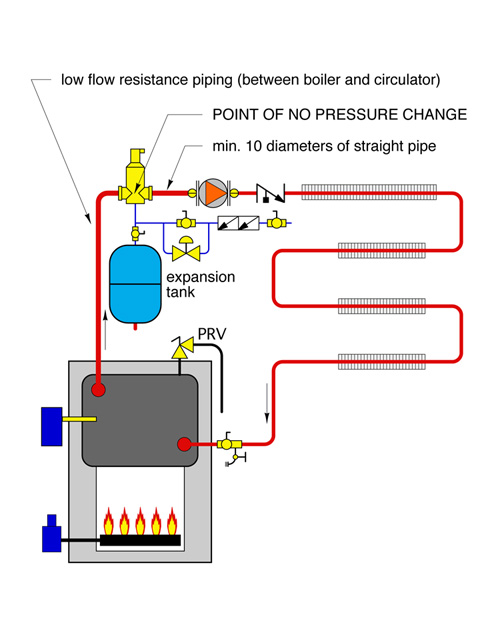

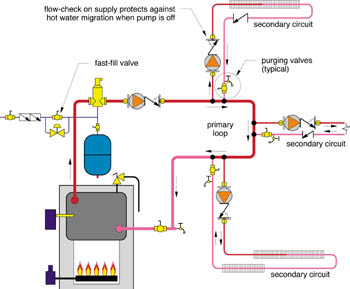

I have my boiler (16 yr old Weil-Mclain Gold) in the garage, with pipes feeding through the wall to my utility room, down one level in the basement. This is a constantly circulating loop of hot water. The manifold in the basement picks off hot water from that loop as needed through a variable speed pump to feed my manifold that supplies warm water to 12 loops of radiant floor heating.

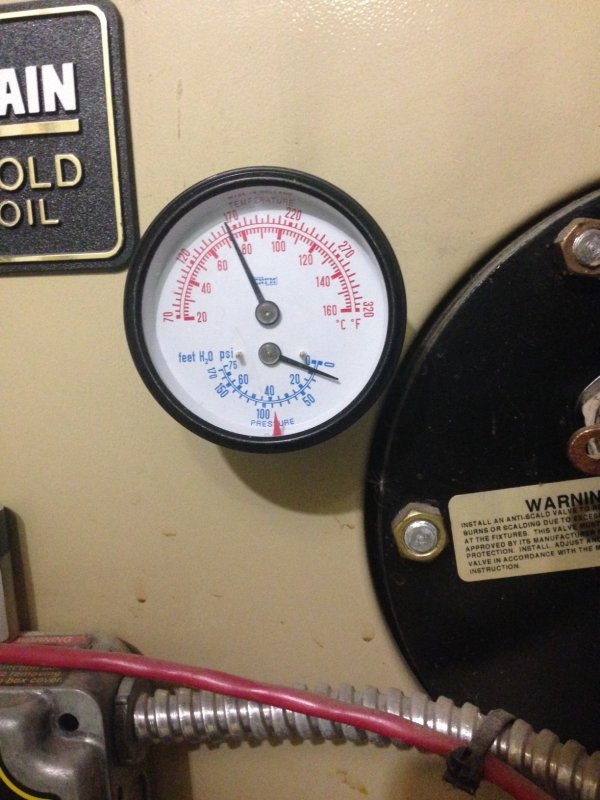

Every fall, when it's time to boot up the system, I start out with air in the system, evidenced by the sound of water moving through the boiler loop pipes. And so at the beginning of each season, I've had someone come to bleed the air out of the system. But as I stated, that person is not available now. The pressure is also very low. When it's working properly, the pressure gauge reads around 15 lbs.

I let a wee bit of air out of the expansion tank, just to check it, and there was a bit of water vapor that came out too. Does that mean that the ET is compromised? When I tap on the tank and give it a little shake, it appears that there is no water in it at all. Is that normal?

I have had issues in the past with the pressure relief valve filling the old coffee can. But currently it's dry, I guess because the pressure is so low. I've read somewhere that if the ET is not working properly, the pressure will increase when the boiler is running, then the PRV will pop open to relieve the pressure. So that means there would then be less water in the system. But I don't understand what effect that would have, nor how the air is getting in.

Any suggestions?

Here are some pics.

My boiler guy has kind of abandoned me, as he took on a bunch of commercial work. I'm hoping you can help me out with an issue that seems to crop up every fall.

I have my boiler (16 yr old Weil-Mclain Gold) in the garage, with pipes feeding through the wall to my utility room, down one level in the basement. This is a constantly circulating loop of hot water. The manifold in the basement picks off hot water from that loop as needed through a variable speed pump to feed my manifold that supplies warm water to 12 loops of radiant floor heating.

Every fall, when it's time to boot up the system, I start out with air in the system, evidenced by the sound of water moving through the boiler loop pipes. And so at the beginning of each season, I've had someone come to bleed the air out of the system. But as I stated, that person is not available now. The pressure is also very low. When it's working properly, the pressure gauge reads around 15 lbs.

I let a wee bit of air out of the expansion tank, just to check it, and there was a bit of water vapor that came out too. Does that mean that the ET is compromised? When I tap on the tank and give it a little shake, it appears that there is no water in it at all. Is that normal?

I have had issues in the past with the pressure relief valve filling the old coffee can. But currently it's dry, I guess because the pressure is so low. I've read somewhere that if the ET is not working properly, the pressure will increase when the boiler is running, then the PRV will pop open to relieve the pressure. So that means there would then be less water in the system. But I don't understand what effect that would have, nor how the air is getting in.

Any suggestions?

Here are some pics.