Joseph Skoler

Member

Hi,

I'm hoping someone could guide me.

I have what I believe is an unusual situation.

We have a well (I believe approximately 300' deep) in the Catskill mountains with a 1hp (could be a 1.5) pump about 100' down (I think).

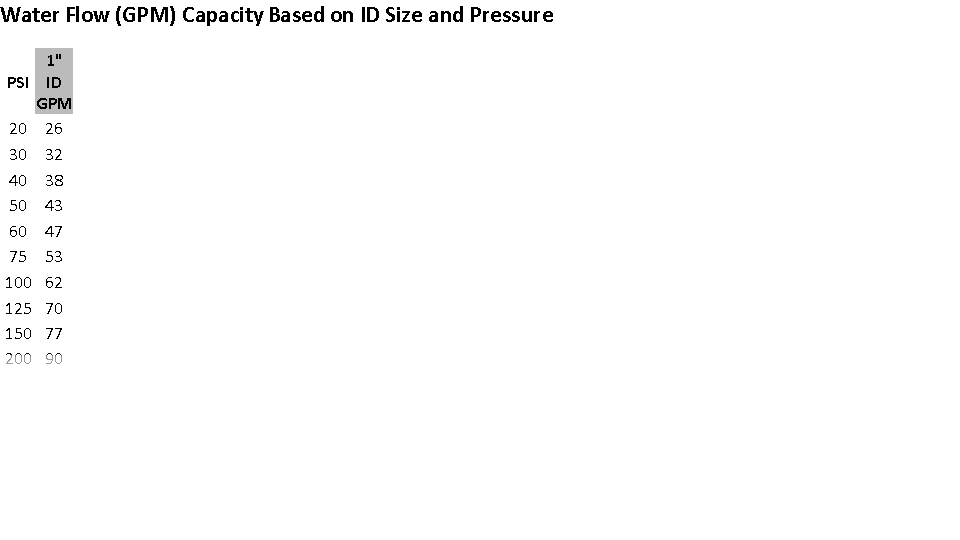

The well head is in a well house with an Amtrol WX-251 62-gallon pressure tank (filters, etc., also) set at 40/60. 1" HDPE then runs to 5 structures (main line branches off at each), with the closest structure about 125' and the farthest about 600'. Two of these structures are infrequently used, seasonal cabins with just 1 full bath. Another structure is also a seasonal cottage with a full bath and kitchen. Another is a year-round small house with full bath and kitchen. Another is a garage/workshop with a bath. In addition, I water the lawn, the garden and occassionally top off a swimming pool.

The pressure drops from about 45 PSI at the second from farthest structure with no water use anywhere to about 25 PSI with a 3/4" valve fully open at that location. And even fluctuates a little (as seen on the pressure gauge I have plumbed in).

I'm hoping to get some expert's thoughts on putting in a second pressure tank (more like a holding tank as it will not have a pressure switch and therefore will not control the well pump) at the central structure (the garage/workshop, which is pushing 400' from the well and central to the 5 structures).

Does this make sense? My goal is to have greater and more consistent pressure and flow volume.

Is there a better way to do this?

Thank you,

Joseph

I'm hoping someone could guide me.

I have what I believe is an unusual situation.

We have a well (I believe approximately 300' deep) in the Catskill mountains with a 1hp (could be a 1.5) pump about 100' down (I think).

The well head is in a well house with an Amtrol WX-251 62-gallon pressure tank (filters, etc., also) set at 40/60. 1" HDPE then runs to 5 structures (main line branches off at each), with the closest structure about 125' and the farthest about 600'. Two of these structures are infrequently used, seasonal cabins with just 1 full bath. Another structure is also a seasonal cottage with a full bath and kitchen. Another is a year-round small house with full bath and kitchen. Another is a garage/workshop with a bath. In addition, I water the lawn, the garden and occassionally top off a swimming pool.

The pressure drops from about 45 PSI at the second from farthest structure with no water use anywhere to about 25 PSI with a 3/4" valve fully open at that location. And even fluctuates a little (as seen on the pressure gauge I have plumbed in).

I'm hoping to get some expert's thoughts on putting in a second pressure tank (more like a holding tank as it will not have a pressure switch and therefore will not control the well pump) at the central structure (the garage/workshop, which is pushing 400' from the well and central to the 5 structures).

Does this make sense? My goal is to have greater and more consistent pressure and flow volume.

Is there a better way to do this?

Thank you,

Joseph