JBW2017

New Member

My 37 to 40 year old submersible well pump in Michigan finally gave out about a month ago and does not want to be extracted.

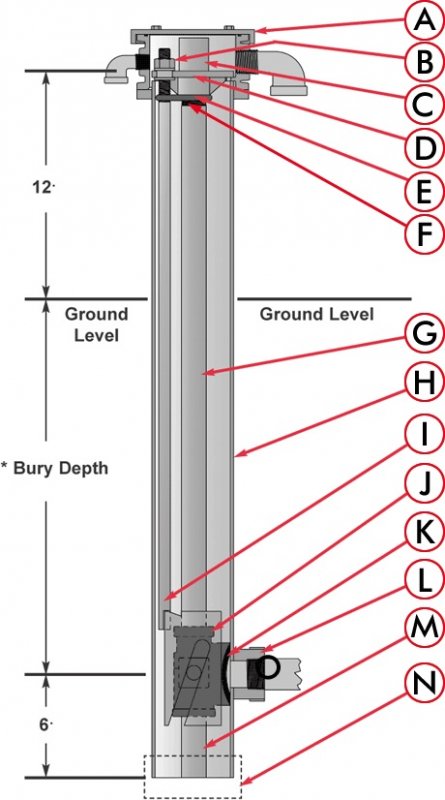

The well is about 35 feet deep and the casing is topped with a Merrill Mfg "Pitless Unit". I have managed to loosen the sliding mechanism in the "pitless unit" that presses the pitless fixture with O ring against the horizontal outlet that leads to the house, so that is not the problem that is preventing the removal of the pump. (Note: The Merrill people have been very helpful in providing info about the well-made unit.-- sideview diagram first photo below) There has never been any maintenance required for the well system (except a new pressure tank) since it was installed around 1977-1980. The well drilling company is out of business and the driller has moved to Florida.

The water from the well has contained a lot of iron -- enough to require an iron filter unit in front of a water conditioner -- so I would assume there is a significant build-up of deposits around the inside of the casing-- enough to not allow any movement of the submersible pump, galvanized outlet pipe, or the attached innards of the pitless unit. Since the water pressure has dropped off to around 22 PSI for the past several years, I also assume that water has been restricted from entering the pump by the buildup and may be responsible for the pump's failure.

The only opening of any size in the top plate of the pitless unit is the notch for the 220v electrical lines to the pump (second photo below). I suppose I could heat up and bend back the sides of the support plate with an oxyacetylene torch to get a look inside the casing, but the sliding mechanism of the pitless adapter would block further access and prevent any deep inspection of what is preventing the removal of the pump.

I have read about Hydrochloric acid (HCL) / muriatic acid used to eat away such iron build-ups, but my neighbor's well is only 25 feet away and I do not want to cause any problems for them.

Does anyone have any suggestions on how to extract the pump? Thanks in advance! --JB

The well is about 35 feet deep and the casing is topped with a Merrill Mfg "Pitless Unit". I have managed to loosen the sliding mechanism in the "pitless unit" that presses the pitless fixture with O ring against the horizontal outlet that leads to the house, so that is not the problem that is preventing the removal of the pump. (Note: The Merrill people have been very helpful in providing info about the well-made unit.-- sideview diagram first photo below) There has never been any maintenance required for the well system (except a new pressure tank) since it was installed around 1977-1980. The well drilling company is out of business and the driller has moved to Florida.

The water from the well has contained a lot of iron -- enough to require an iron filter unit in front of a water conditioner -- so I would assume there is a significant build-up of deposits around the inside of the casing-- enough to not allow any movement of the submersible pump, galvanized outlet pipe, or the attached innards of the pitless unit. Since the water pressure has dropped off to around 22 PSI for the past several years, I also assume that water has been restricted from entering the pump by the buildup and may be responsible for the pump's failure.

The only opening of any size in the top plate of the pitless unit is the notch for the 220v electrical lines to the pump (second photo below). I suppose I could heat up and bend back the sides of the support plate with an oxyacetylene torch to get a look inside the casing, but the sliding mechanism of the pitless adapter would block further access and prevent any deep inspection of what is preventing the removal of the pump.

I have read about Hydrochloric acid (HCL) / muriatic acid used to eat away such iron build-ups, but my neighbor's well is only 25 feet away and I do not want to cause any problems for them.

Does anyone have any suggestions on how to extract the pump? Thanks in advance! --JB