RockfordPI

New Member

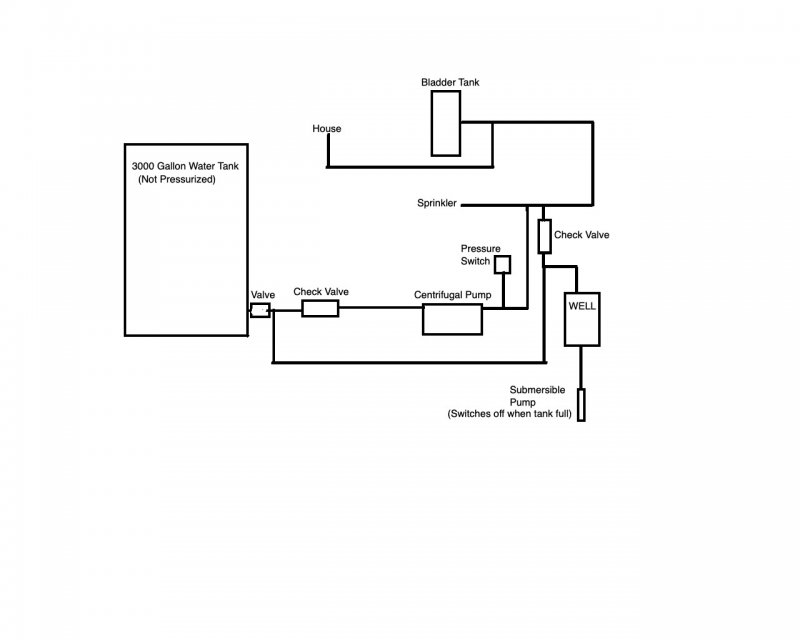

Will the pump system in the attached pic work (scroll down to see all)? I am specifically worried about the pumps pumping against each other and the check valve configurations/locations.

Background. Originally had only the 240' well, submersible pump, and large bladder tank. Initially (20 years ago) well was producing 4-5 gallons/minute. Recently installed Sod and tried to water. Discovered well is now only producing 1/2 - 1/3 gallon/minute (which apparently was sufficient to supply household given the larger bladder tank and pumptec protector)

6 weeks lead time here to get a well drilled (I wish I knew how to drill wells as one local driller is 87, the other is 74, looks like a great business opportunity).

So, I installed a 3000 gallon water tank outside. Submersible pump now fills tank from well. Franklin Pumptec shuts off sub pump on run dry, delays for 90 minutes and restarts, otherwise Sub pump shuts off on tank full.

I added a centrifugal pump to provide water/pressure to the house and sprinklers.

I also left the sub pump connected to the house so I could, if needed, close the valve to the 3000 gallon tank and revert to pumping water directly from well into house (with pressure switch setup accordingly).

The four states are

1 No Pumps Running (I am guessing I am OK there)

2. Submersible only running

3. Centrifugal only running

4. BOTH pumps running (this one has me concerned)

Systems seems to work OK, but I am paranoid about the sound of the centrifugal pump sometimes. Any feedback is appreciated.

Background. Originally had only the 240' well, submersible pump, and large bladder tank. Initially (20 years ago) well was producing 4-5 gallons/minute. Recently installed Sod and tried to water. Discovered well is now only producing 1/2 - 1/3 gallon/minute (which apparently was sufficient to supply household given the larger bladder tank and pumptec protector)

6 weeks lead time here to get a well drilled (I wish I knew how to drill wells as one local driller is 87, the other is 74, looks like a great business opportunity).

So, I installed a 3000 gallon water tank outside. Submersible pump now fills tank from well. Franklin Pumptec shuts off sub pump on run dry, delays for 90 minutes and restarts, otherwise Sub pump shuts off on tank full.

I added a centrifugal pump to provide water/pressure to the house and sprinklers.

I also left the sub pump connected to the house so I could, if needed, close the valve to the 3000 gallon tank and revert to pumping water directly from well into house (with pressure switch setup accordingly).

The four states are

1 No Pumps Running (I am guessing I am OK there)

2. Submersible only running

3. Centrifugal only running

4. BOTH pumps running (this one has me concerned)

Systems seems to work OK, but I am paranoid about the sound of the centrifugal pump sometimes. Any feedback is appreciated.