aarpcard

New Member

Hello All,

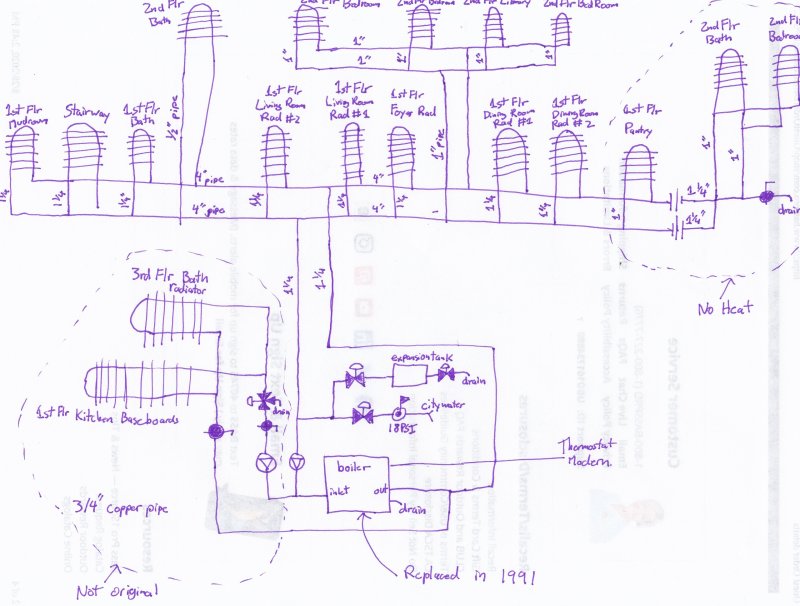

I'm not a trained plumber so forgive any mistakes on my part. I have (I think) a fairly complex hydronic heating system in my house. The majority of the system is 112 years old comprising of large cast iron radiators and black pipe. I believe this system was originally 2-pipe steam but was converted to water at some point.

The boiler is 1991 vintage.

At some point the original radiators in the kitchen and 3rd floor were removed from the original loop and replaced with baseboards in the kitchen, and a smaller radiator in the 3rd floor bathroom on a new, all copper 2nd loop with it's own circulating pump. (electric baseboards on the rest of the 3rd floor). I estimate this was done around 2006.

The system operates at 18PSI. All of the radiators have been bled and balanced (and the majority have new shutoff valves).

The issue I'm having is the radiators circled on the right of the below schematic at the end of the primary loop, take an extremely long time to heat up. The boiler has to be cranked for 12+ hours before they get any heat.

My guess is it's a circulation issue because they are at the end of the loop (and the last two are on the second floor). Checking the pressure in these radiators from the bleed valves indicated full pressure (18PSI) so I'm pretty sure it is not a blockage.

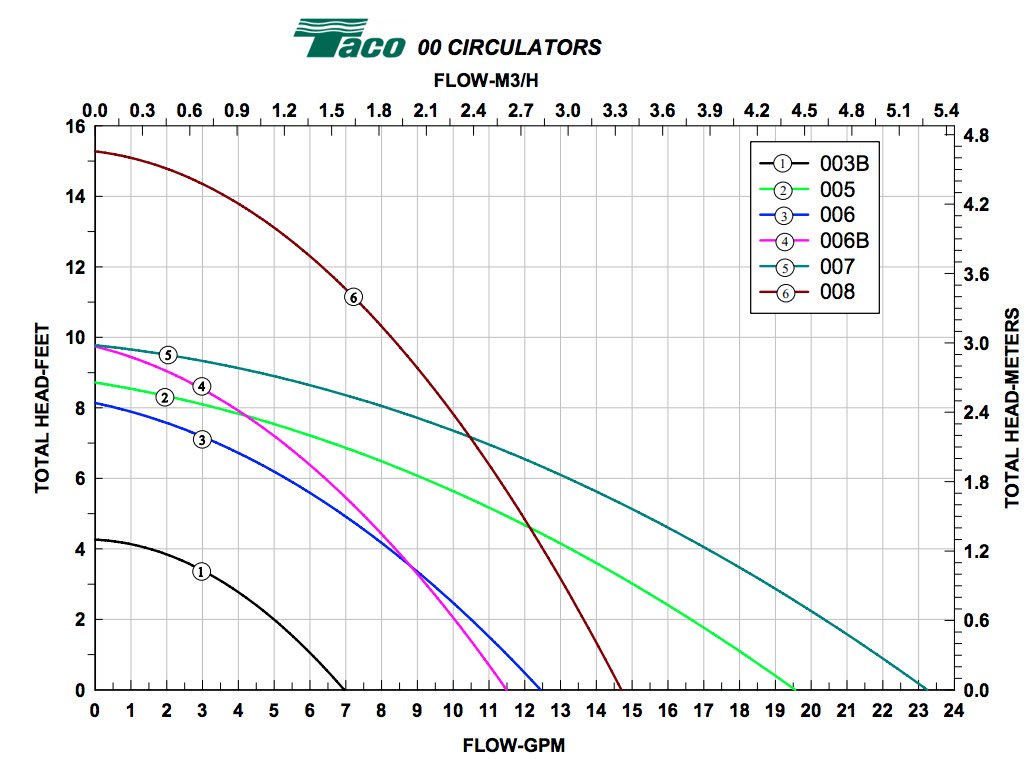

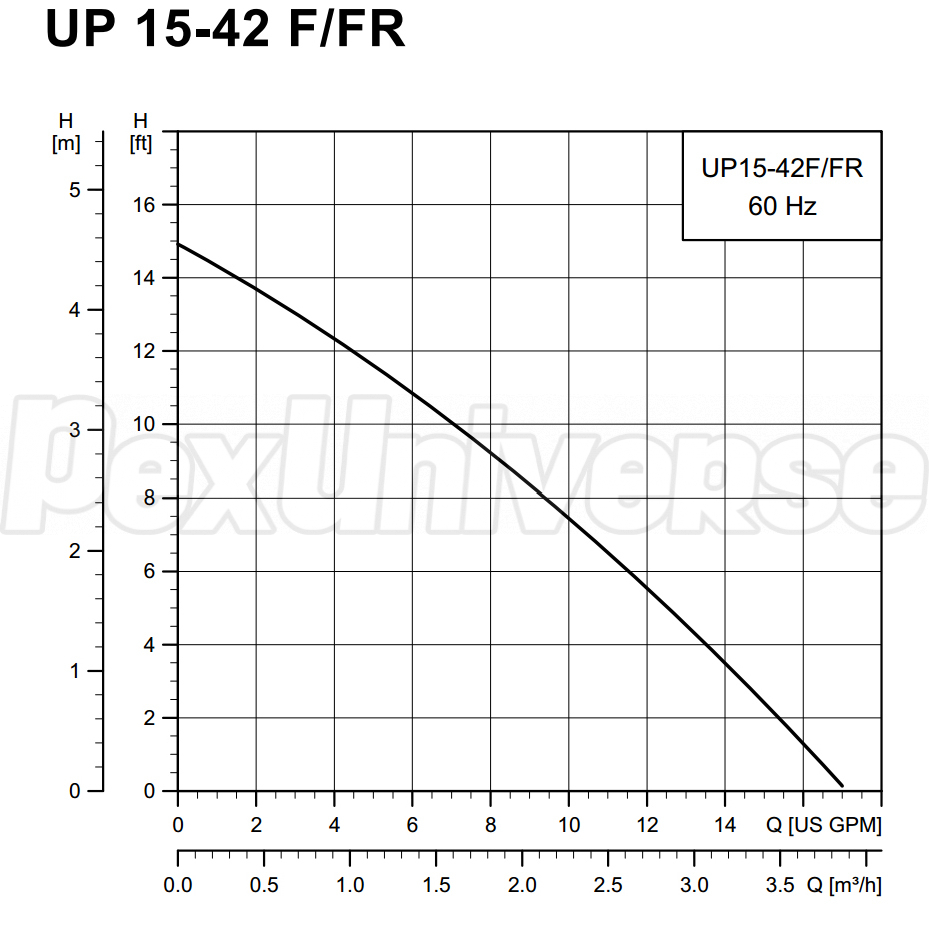

My uneducated guess is I need a second circulating pump somewhere on the primary loop, but I don't know where nor if that is the right solution. Any ideas/advise would be appreciated. See below roughly drawn schematic.

I'm not a trained plumber so forgive any mistakes on my part. I have (I think) a fairly complex hydronic heating system in my house. The majority of the system is 112 years old comprising of large cast iron radiators and black pipe. I believe this system was originally 2-pipe steam but was converted to water at some point.

The boiler is 1991 vintage.

At some point the original radiators in the kitchen and 3rd floor were removed from the original loop and replaced with baseboards in the kitchen, and a smaller radiator in the 3rd floor bathroom on a new, all copper 2nd loop with it's own circulating pump. (electric baseboards on the rest of the 3rd floor). I estimate this was done around 2006.

The system operates at 18PSI. All of the radiators have been bled and balanced (and the majority have new shutoff valves).

The issue I'm having is the radiators circled on the right of the below schematic at the end of the primary loop, take an extremely long time to heat up. The boiler has to be cranked for 12+ hours before they get any heat.

My guess is it's a circulation issue because they are at the end of the loop (and the last two are on the second floor). Checking the pressure in these radiators from the bleed valves indicated full pressure (18PSI) so I'm pretty sure it is not a blockage.

My uneducated guess is I need a second circulating pump somewhere on the primary loop, but I don't know where nor if that is the right solution. Any ideas/advise would be appreciated. See below roughly drawn schematic.