TimCee

New Member

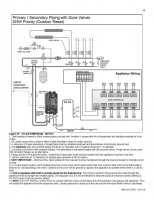

I am new to the forum but have gotten a lot of good advice here as a lurker but I need to know what I should do in my situation. I replaced an old (from the 70's) boiler with a new Westinghouse WBRCNG140W 140k BTU Condensing Natural Gas Combi Boiler. It has a inline circulator on the supply side and I am wondering if I should place my new second circulator on the supply side as well. My system has the zone valves on the supply side and the old boiler had the circulator on the return. I purchased a new Taco VR1816-HY2-FC2A00 variable speed pump and I was going to place it back on the same return side but the installation manual says I should place it on the supply side. The two circulators would only be 3 feet apart, I am not sure if this would matter but two pumps that close just doesn't make sense to me. I would think placing the Taco pump on the return would work better. It appears I have to place closely-spaced-tees as well with this setup (or do I) so I am going to place that near the boiler. I would like to pipe this as much as possible because I would like a certified tech finish this up. Any thoughts or opinions would be greatly appreciated, thanks.