DIYER39

Member

I hope everyone is healthy and staying safe out there.

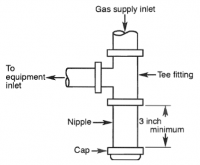

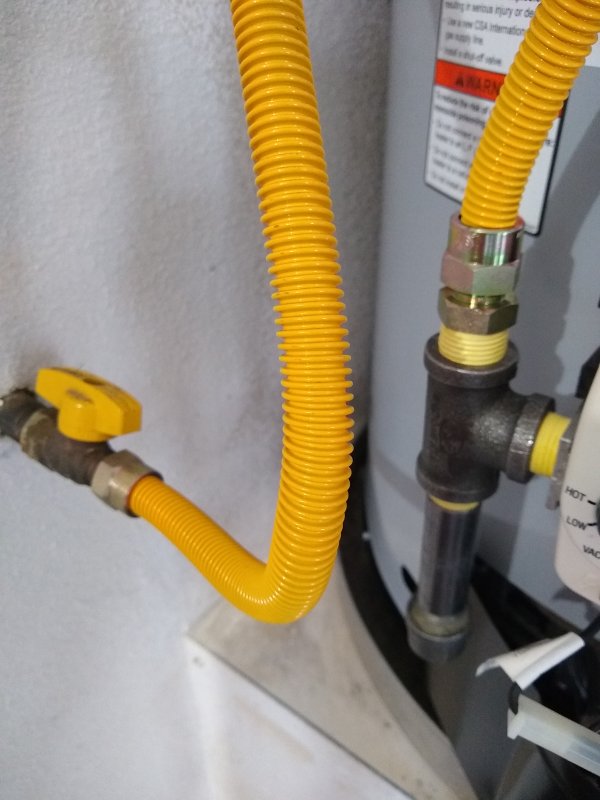

I recently installed a new water heater exactly as the old one was installed by a plumbing company. Everything went smoothly. Shortly after, I learned about new code (2016) that requires the sediment trap to be installed before the flex line instead of after the flex line.

What additional fittings would I need to move the sediment trap? So far I can only think of two. #1---A female to male adapter from the valve to the larger T fitting. #2---Another flare fitting for the gas line to the control valve.

I would really appreciate if someone give me the proper names, metal, and thread of these fittings and let me know if there is anything else that I am forgetting? I dont see this job being too hard but if I use the wrong thread, metal, or adapter, things can quickly go wrong. The valve to T fitting is my main concern because the sizes look different. Any advice is greatly appreciated.

I recently installed a new water heater exactly as the old one was installed by a plumbing company. Everything went smoothly. Shortly after, I learned about new code (2016) that requires the sediment trap to be installed before the flex line instead of after the flex line.

What additional fittings would I need to move the sediment trap? So far I can only think of two. #1---A female to male adapter from the valve to the larger T fitting. #2---Another flare fitting for the gas line to the control valve.

I would really appreciate if someone give me the proper names, metal, and thread of these fittings and let me know if there is anything else that I am forgetting? I dont see this job being too hard but if I use the wrong thread, metal, or adapter, things can quickly go wrong. The valve to T fitting is my main concern because the sizes look different. Any advice is greatly appreciated.

Last edited by a moderator: