Okay. Sometimes it happens. I got a call from a homeowner in a highrise condo that had a repair done by another company and it was still leaking.

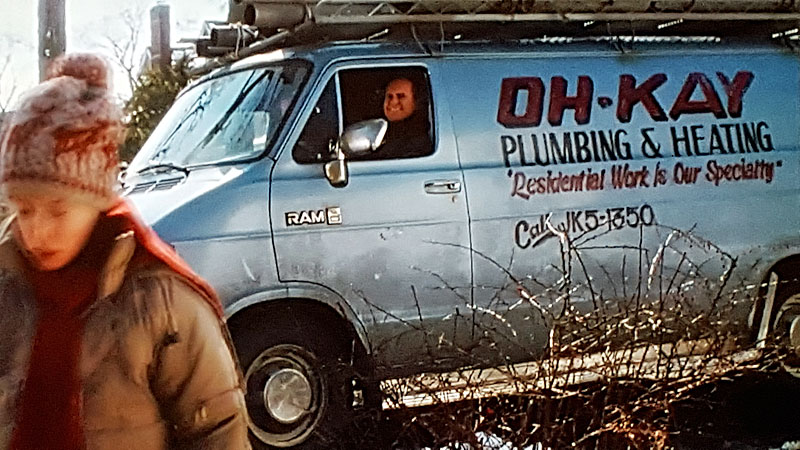

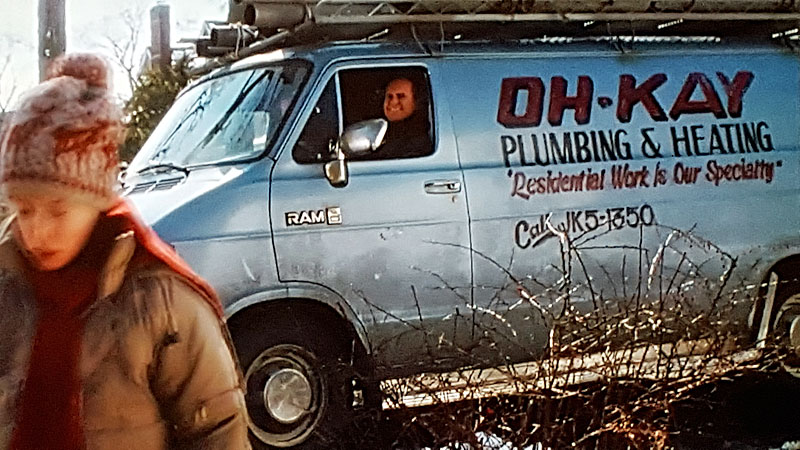

No. I wasn't this company, but it could have been someone like this. I love this. A plumbing company that is just Okay.

Normally you can cut PEX and push a Sharkbite on and you're good to go. You can see the water leak behind the Sharkbite.

Lucky for me, and I mean lucky. The PEX in the wall is the same stuff I carry and have tools for. I went ahead and extended the valve out a ways, and added a male adapter that makes changing the shutoff easier for the next guy. They guy I followed had a muti-turn valve which I replaced with Dahl. I do like 1/4 turn shutoffs.

No. I wasn't this company, but it could have been someone like this. I love this. A plumbing company that is just Okay.

Normally you can cut PEX and push a Sharkbite on and you're good to go. You can see the water leak behind the Sharkbite.

Lucky for me, and I mean lucky. The PEX in the wall is the same stuff I carry and have tools for. I went ahead and extended the valve out a ways, and added a male adapter that makes changing the shutoff easier for the next guy. They guy I followed had a muti-turn valve which I replaced with Dahl. I do like 1/4 turn shutoffs.