The pumping head of the heat exchanger in the Navien is much higher than a cast iron boiler- you may or may not be able to push enough flow through that HX to support what the radiation needs. If you have the software or are really good with a paper & pencil it's possible to figure out what's needed and what's possible and spec the pump, but if you're not sure it's easier to just plumb it primary/secondary with a hydraulic separator (such as the pre-engineered manifold).

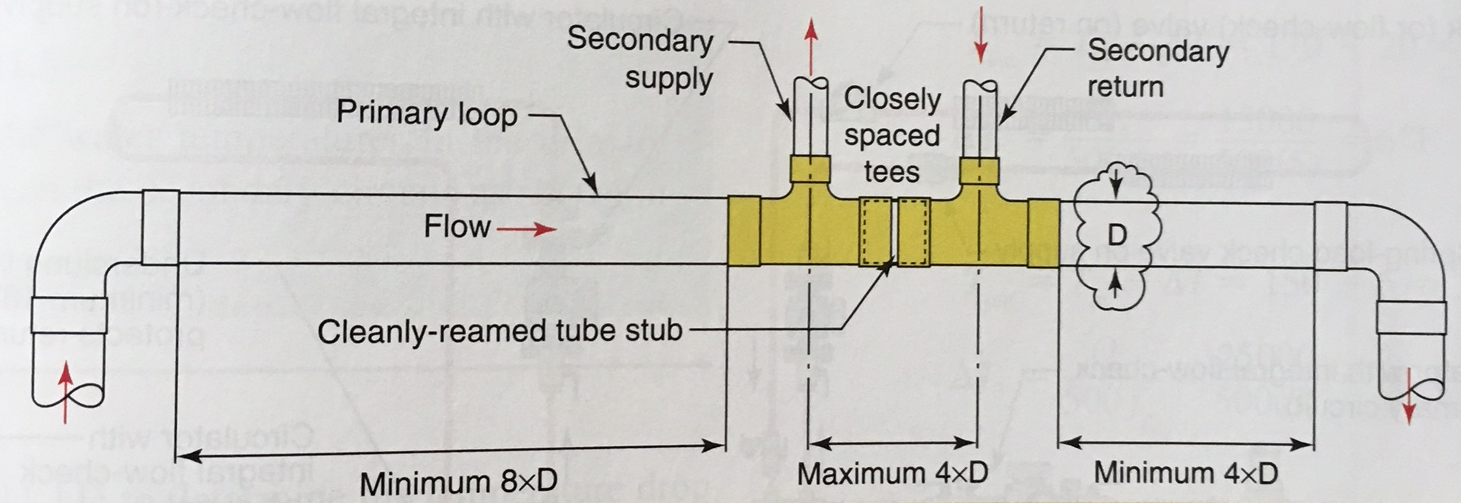

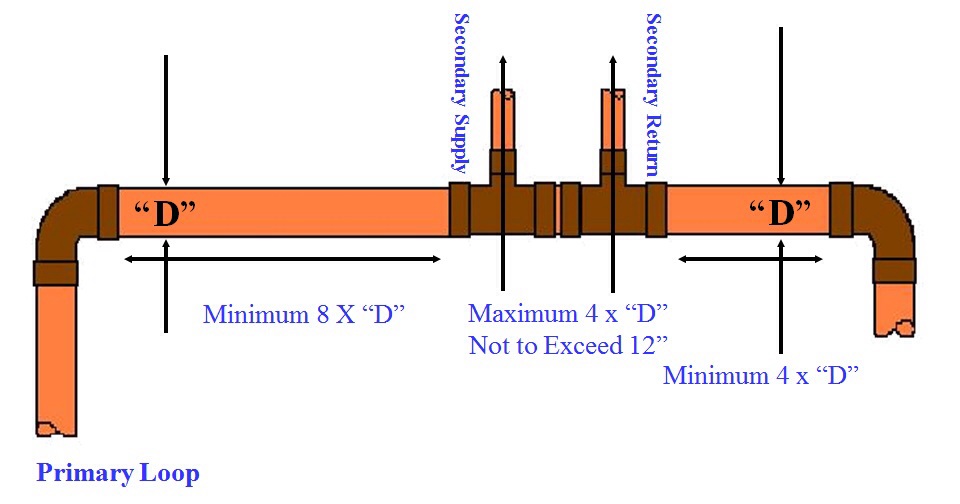

You can make your own hydraulic separator out of fittings using closely spaced tees, but the tees have to be spaced very closely to achieve adequate separation between the primary (boiler loop) and secondary (radiation loop) flows.

How much radiation, is there on this system, and which model Navien? It's pretty common to see these condensing boilers hooked up to systems that don't have enough radiation to run the boiler in condensing mode without short-cycling. See this bit o' bloggery for the napkin math on that.

The secondary supply/return can have the same diameter as primary loop pipe? The image is clearly telling that dimensions are different, but I just asking.