Geobrick

Member

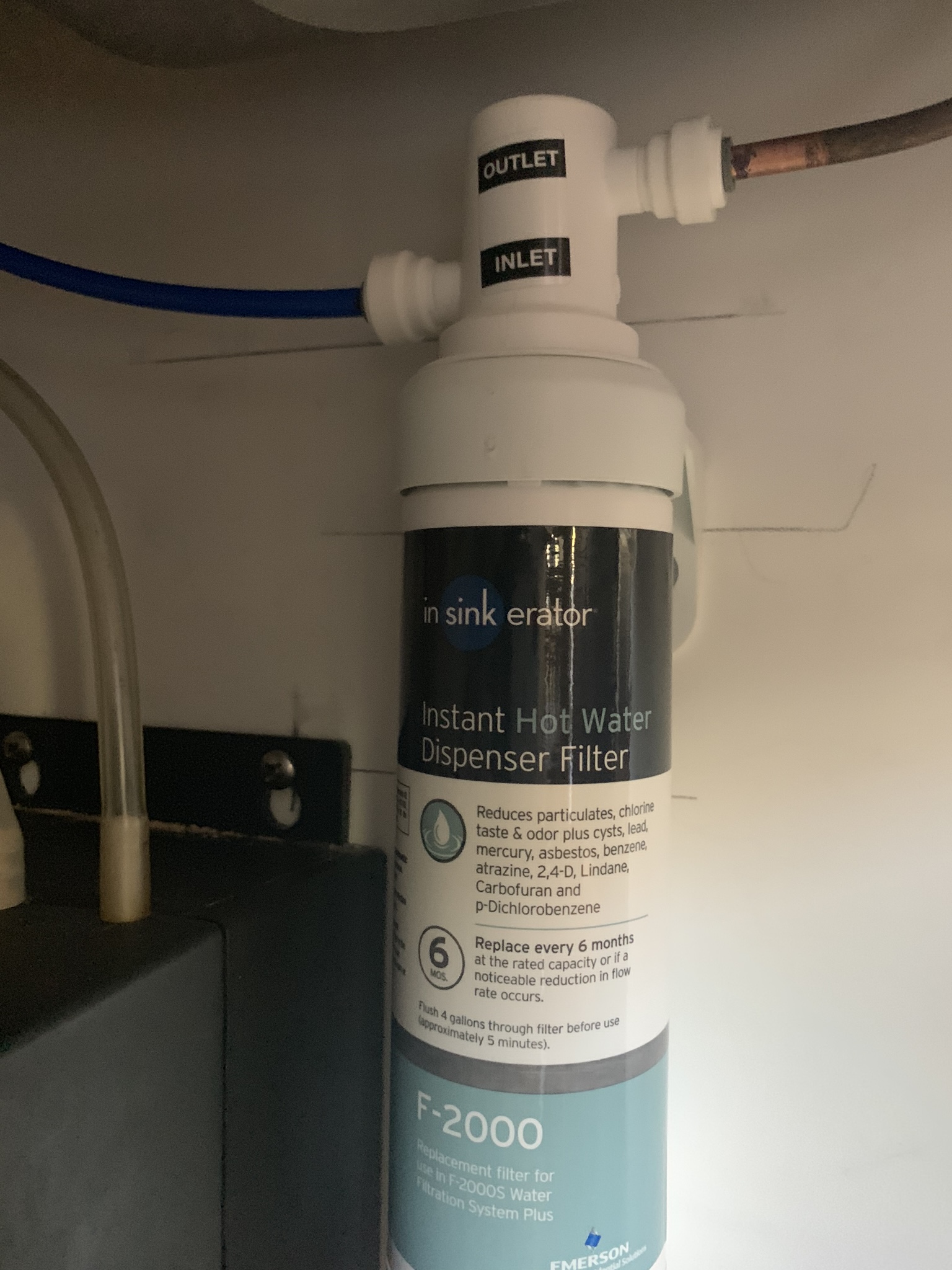

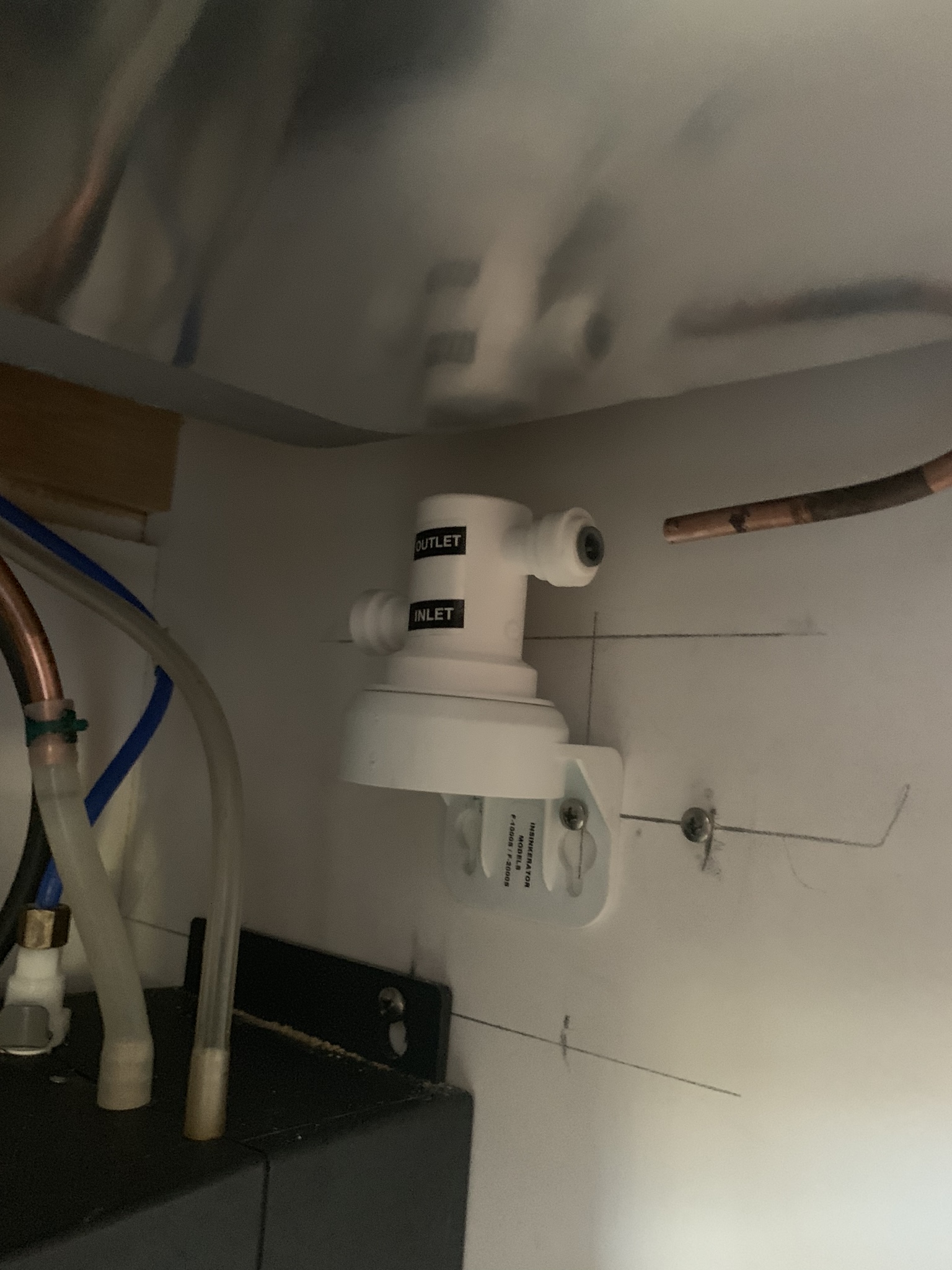

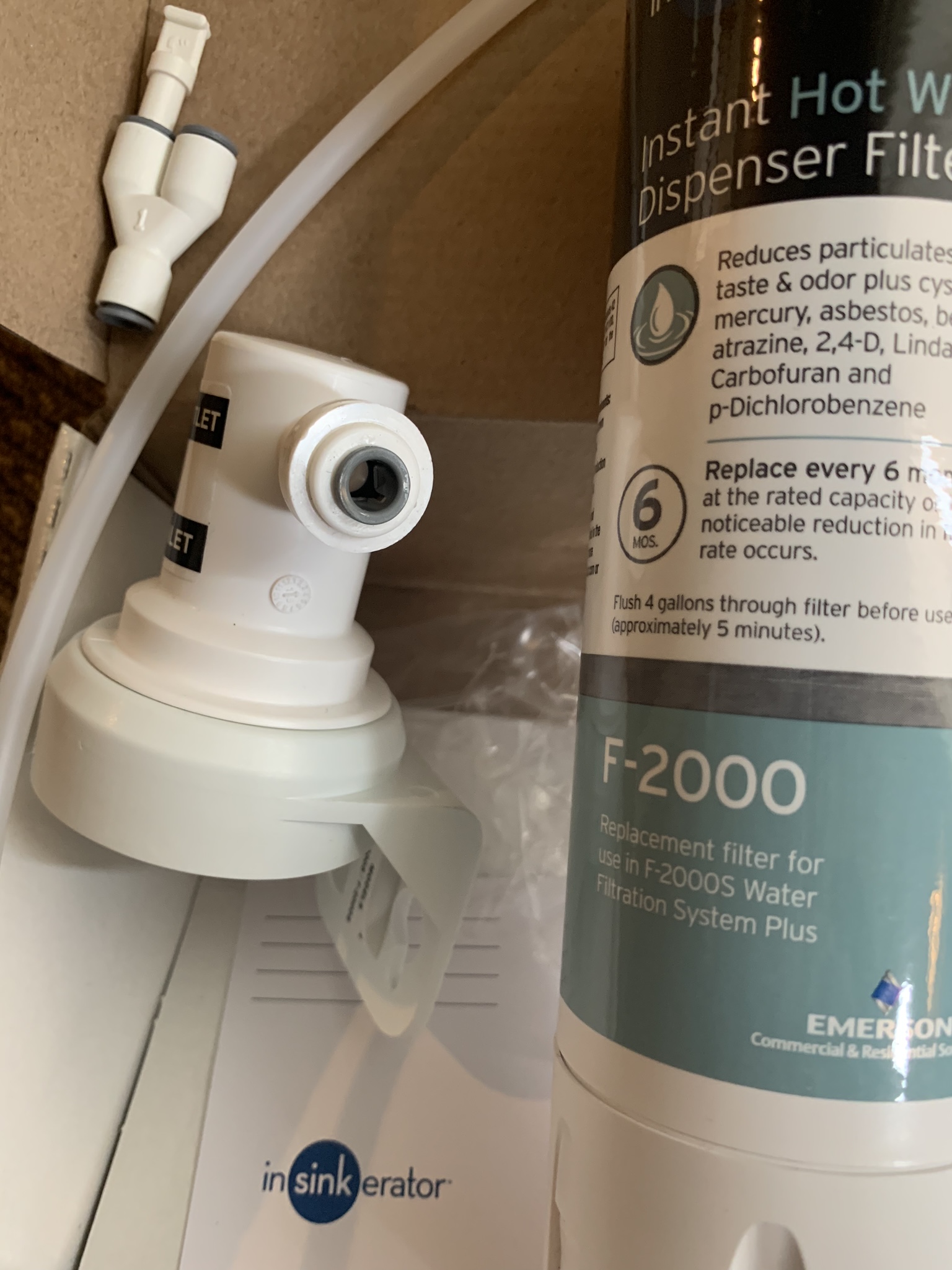

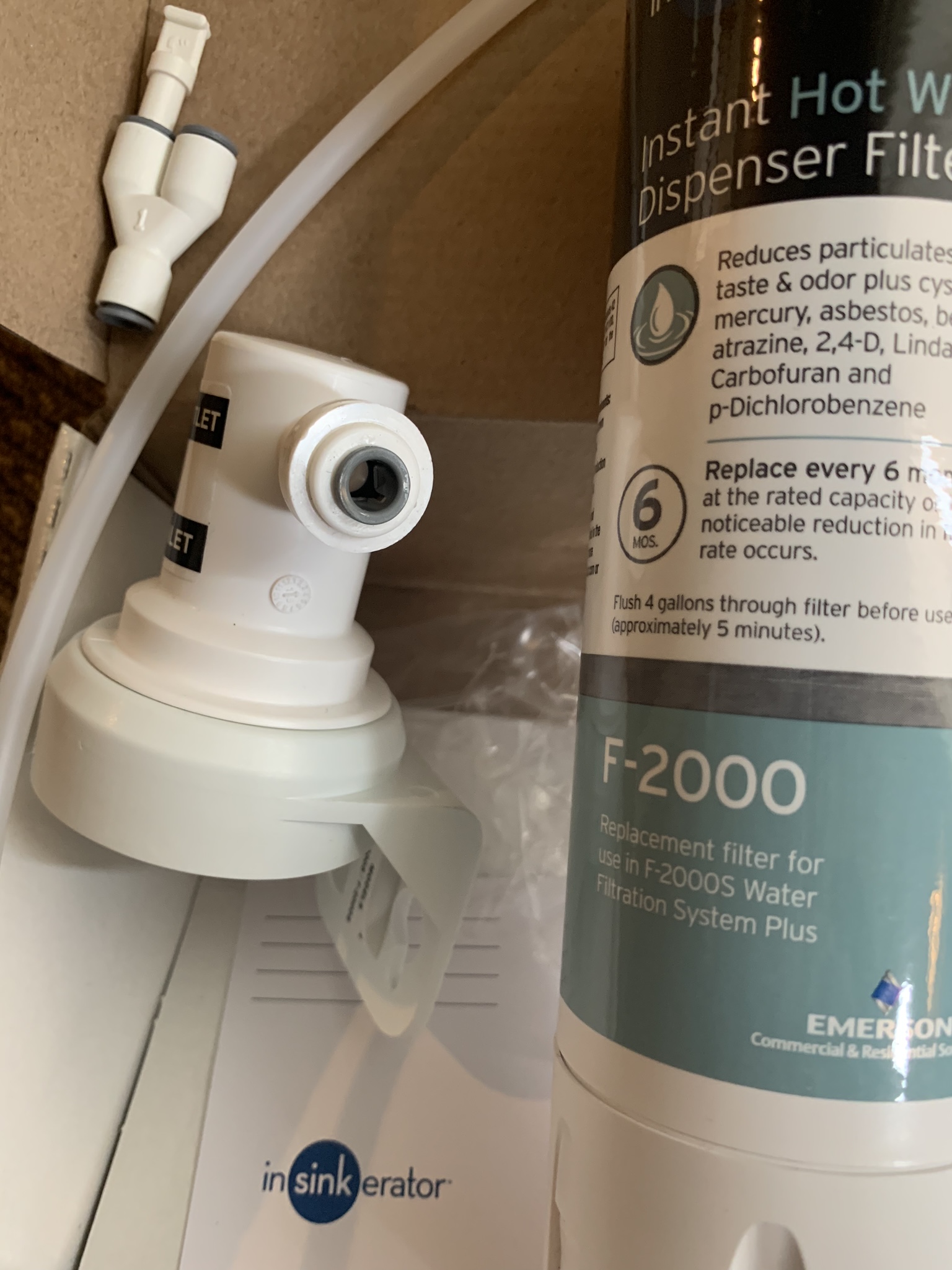

Can I connect 1/4" copper tubing to this quick connect?

I'm 95% sure I can do this since I know I can use the John Guest Quick Connects to connect to copper tubing but I don't know that the quick connects built into this Insinkerator filter housing are actually the John Guest type.

I'm 95% sure I can do this since I know I can use the John Guest Quick Connects to connect to copper tubing but I don't know that the quick connects built into this Insinkerator filter housing are actually the John Guest type.