CountryBumkin

Active Member

I purchased some brass PEX couplers made for soldering to copper pipe.

These https://www.supplyhouse.com/Wirsbo-...X-LF-Brass-Sweat-Adapter-1-2-PEX-x-1-2-Copper when I tried to solder these I could not get the solder to flow into the joint. I cleaned both fitting and pipe with a wire pipe fitting brush and used soldering flux on both pieces. Then I heated the copper and brass fitting with my MAP torch (making sure to get the brass hot) but the solder just "rolled off" the fitting, it would not flow into the joint.

What did I do wrong?

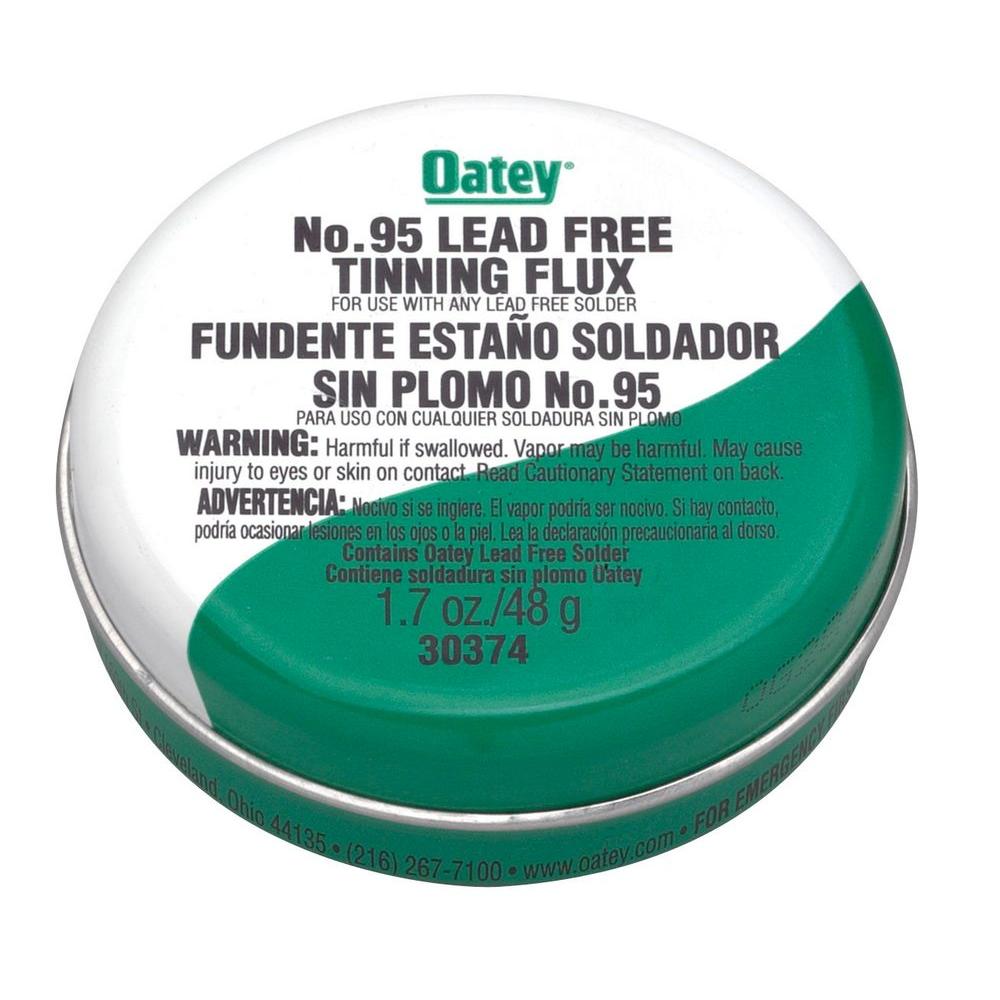

Is there a special flux or solder for this?

I used the same flux/solder that works fine on my copper to copper joints.

These https://www.supplyhouse.com/Wirsbo-...X-LF-Brass-Sweat-Adapter-1-2-PEX-x-1-2-Copper when I tried to solder these I could not get the solder to flow into the joint. I cleaned both fitting and pipe with a wire pipe fitting brush and used soldering flux on both pieces. Then I heated the copper and brass fitting with my MAP torch (making sure to get the brass hot) but the solder just "rolled off" the fitting, it would not flow into the joint.

What did I do wrong?

Is there a special flux or solder for this?

I used the same flux/solder that works fine on my copper to copper joints.