skylonda

New Member

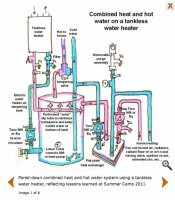

Trying to install staple up wood floor hydronic combined (maybe add a radiator or two) for a seasonal cabin about 1100sf. will have approx. 1100ft 1/2" pex with Al emitter plates. There is r19 batt in cathedral ceiling, most of walls have no insulation other than 3/4" interior and exterior solid wood siding, will add r19 underfloor , later insulate walls with foam. Half windows are newer double pane, others are single. Lots of air leaks 1950s cabin. At Lake Tahoe, approx 6800degree days, would use heat in months where high/low are approx. 15/40. Wondering if I can get a Navien NCB-240 Combi to run the hydronic heat without short cycling, I think you can reduce max. output to 50% and I plan to a run lower temp to the staple up, might add runtal type radiators if more extraction of heat is needed ( all on a single zone/ tstat). I realize the occupants of the small building will only need less output than this can produce but wanted to try to make it work mainly for snow season short term usage- glycol also). This is unit is near new, was removed from a SF bay area house due to short cycling problems, I had nothing to do with that and do not know what was attempted to make it work.