Geobrick

Member

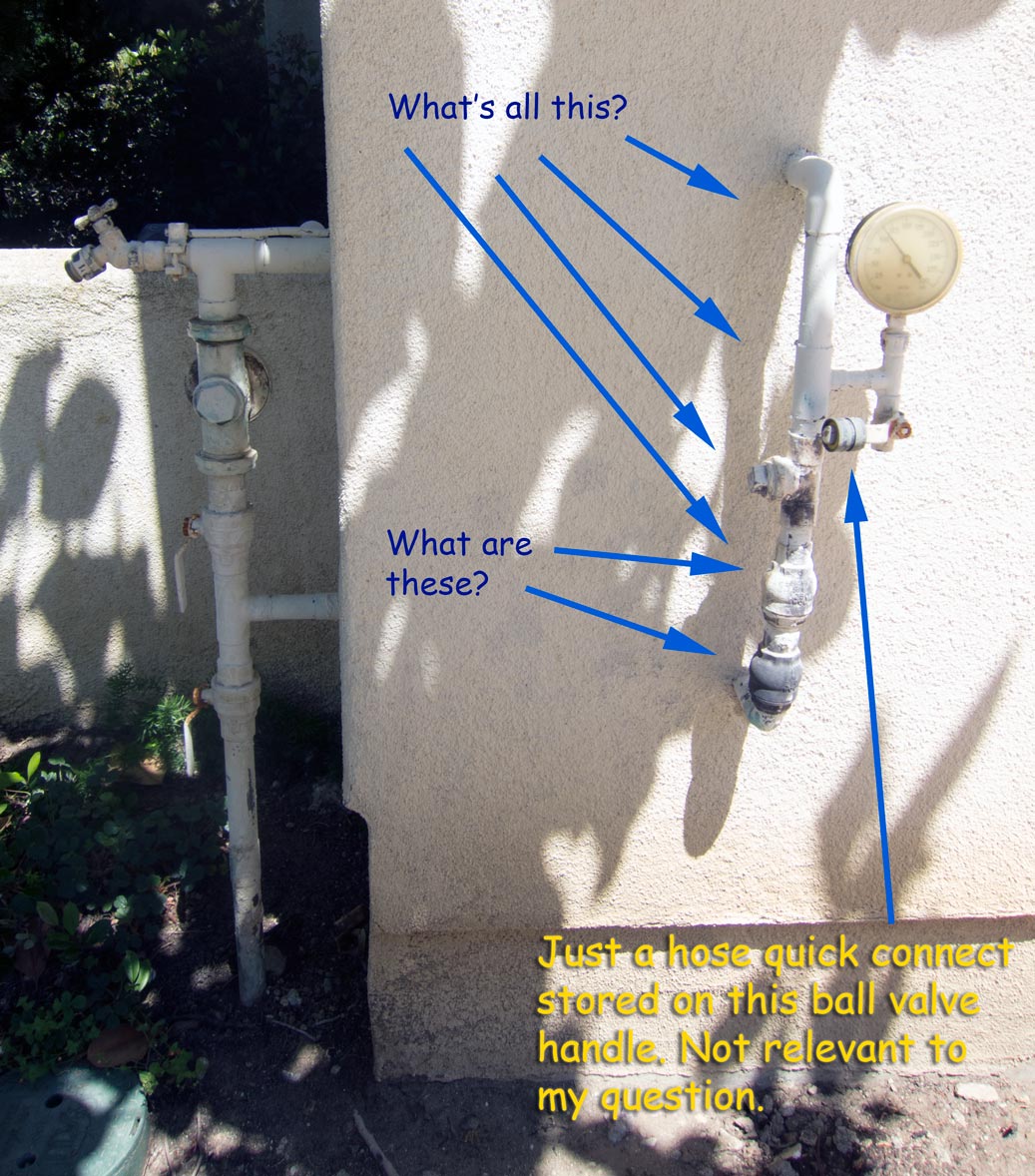

1) I have a Wilkins 70 Pressure Reducing Valve that's about 17 years old. How long before I should expect to have to replace (or rebuild) it?

2) I looked at the Zurn-Wilkins website and noticed they no longer sell the model 70. It's now a 70XL but they no longer make the size I have which is 1-1/4" (double union). I would hope to get something with the same dimensions that would be interchangeable with the old one so I can just install the new one without redoing the piping. Any thoughts on what to do here? I saw they make an NR3XL model with a double union but can't be sure the dimensions are right. The spec sheet on their site shows a drawing with a dimension "A" that seems to imply they are measuring from the ends of the union fittings instead of the valve body.

3) What do the professionals use for the gaskets on union fittings? This is a 1-1/4" valve so what size union gasket should I be looking for (I assume 1-1/4" but I can't be sure)? I see some wetness on the top of the valve and want to have some replacements on hand if I decide to mess with it.

4) How do I make my uploaded images appear as thumbnails until clicked on?

2) I looked at the Zurn-Wilkins website and noticed they no longer sell the model 70. It's now a 70XL but they no longer make the size I have which is 1-1/4" (double union). I would hope to get something with the same dimensions that would be interchangeable with the old one so I can just install the new one without redoing the piping. Any thoughts on what to do here? I saw they make an NR3XL model with a double union but can't be sure the dimensions are right. The spec sheet on their site shows a drawing with a dimension "A" that seems to imply they are measuring from the ends of the union fittings instead of the valve body.

3) What do the professionals use for the gaskets on union fittings? This is a 1-1/4" valve so what size union gasket should I be looking for (I assume 1-1/4" but I can't be sure)? I see some wetness on the top of the valve and want to have some replacements on hand if I decide to mess with it.

4) How do I make my uploaded images appear as thumbnails until clicked on?

Last edited by a moderator: