FrankBranch

New Member

We live in a log home with a finished loft. At some point a bathroom was added to the loft, the waste drain is plumbed with 3” PVC pipe, with the flange screwed to the subfloor. I believe the plumber used an inside flange, since the toilet is very hard to set due to the horn tending to interfere with the inside of the flange.

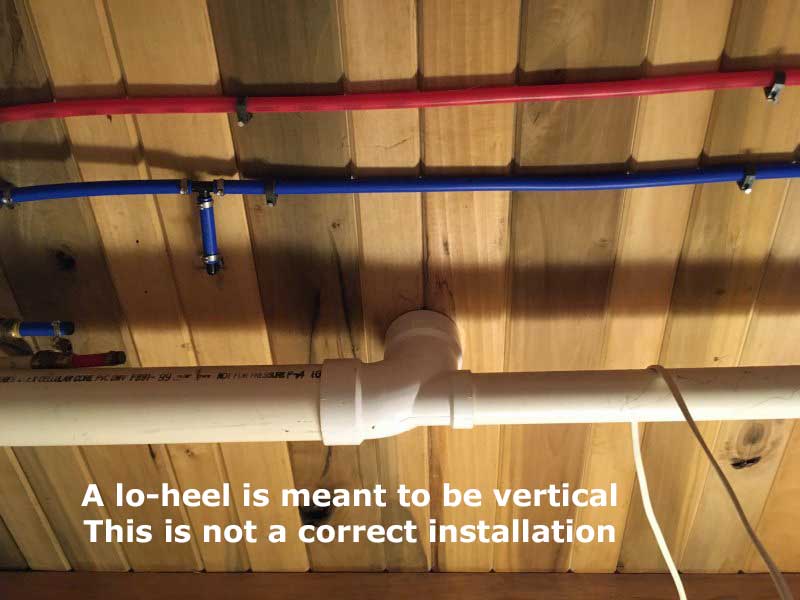

The structure under the bathroom is 4”x 8“ open beams with 1” tongue & groove (which is what you see underneath) overlaid with a ¾” OSB subfloor. The area under the bath was a former laundry room, with the overhead mechanicals concealed with a rather unsightly drop ceiling (made all the worse by periodic leaks from the poorly sealing toilet).

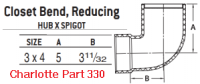

We are starting a remodel where we are expanding the kitchen into the former laundry area. We plan to box in the space between the 4”x8” beams to hide the plumbing, but that means the waste drain under the toilet needs to be as close to the underside of the floor as possible, that way the approx 5’ piping run with ¼” / foot drop stays well within the 8” area established by the beams. The current setup uses a 3” elbow with a low heel inlet, which picks up a lavatory drain.

What are some tricks for installing a toilet with very little underfloor clearance? Is there a “street” configuration closet flange that would fit directly into elbow? A solution that makes the upstairs toilet set easily would be a bonus!

The structure under the bathroom is 4”x 8“ open beams with 1” tongue & groove (which is what you see underneath) overlaid with a ¾” OSB subfloor. The area under the bath was a former laundry room, with the overhead mechanicals concealed with a rather unsightly drop ceiling (made all the worse by periodic leaks from the poorly sealing toilet).

We are starting a remodel where we are expanding the kitchen into the former laundry area. We plan to box in the space between the 4”x8” beams to hide the plumbing, but that means the waste drain under the toilet needs to be as close to the underside of the floor as possible, that way the approx 5’ piping run with ¼” / foot drop stays well within the 8” area established by the beams. The current setup uses a 3” elbow with a low heel inlet, which picks up a lavatory drain.

What are some tricks for installing a toilet with very little underfloor clearance? Is there a “street” configuration closet flange that would fit directly into elbow? A solution that makes the upstairs toilet set easily would be a bonus!