PortlandBill

New Member

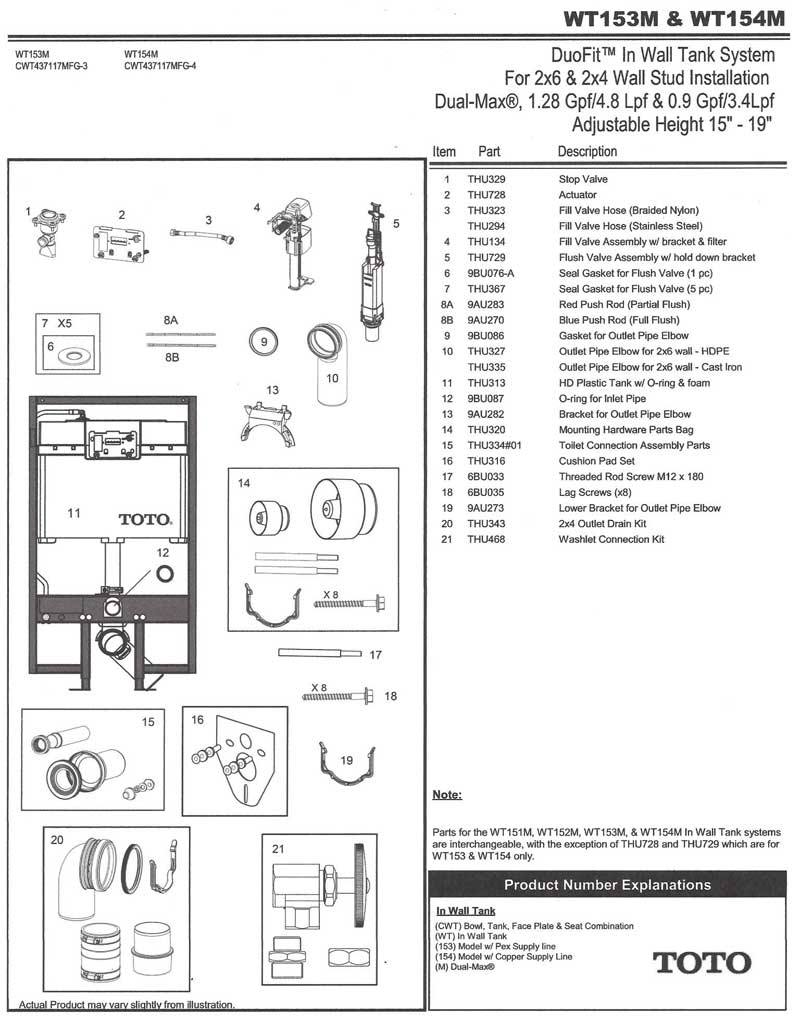

Any suggestions on backing out the cap on the washlet outlet on a Duo-Fit WT153M in-wall tank?

It is jammed in there pretty good. I tried a 9mm hex wrench, worked out it was probably 3/8-inch but the soft brass is by now stripped. I'm trying to avoid removing and replacing the tank, cement-board, and tiles.

I've ordered a Irwin Extractor set with the reverse thread spiral flutes. I'm hoping I can get that in there and get some counter-clockwise force going.

If anyone has other suggestions, this would be very welcome.

BTW, I brought this on myself by installing the tank without first attempting to unscrew and then insert the cap BEFORE tiling. Don't be like Bill, don't be an idiot!

It is jammed in there pretty good. I tried a 9mm hex wrench, worked out it was probably 3/8-inch but the soft brass is by now stripped. I'm trying to avoid removing and replacing the tank, cement-board, and tiles.

I've ordered a Irwin Extractor set with the reverse thread spiral flutes. I'm hoping I can get that in there and get some counter-clockwise force going.

If anyone has other suggestions, this would be very welcome.

BTW, I brought this on myself by installing the tank without first attempting to unscrew and then insert the cap BEFORE tiling. Don't be like Bill, don't be an idiot!