Dana, never thought of the down time for the radiant heat and stagnant water. I was doing good until I figured in the shower. I would be able to drain water recovery, do they work well?

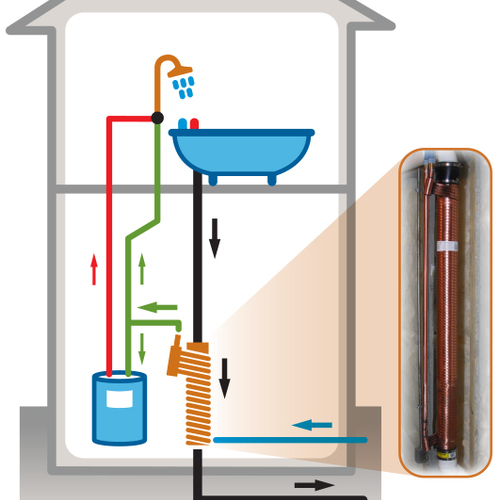

Drainwater heat recovery works well, provided there is sufficient height. Natural Resources Canada (NRCAN) developed a standardized test protocol, and most (not all) vendors use third party test companies to run the protocol on their products. NRCAN maintains

a searchable online database for comparing performance between models.

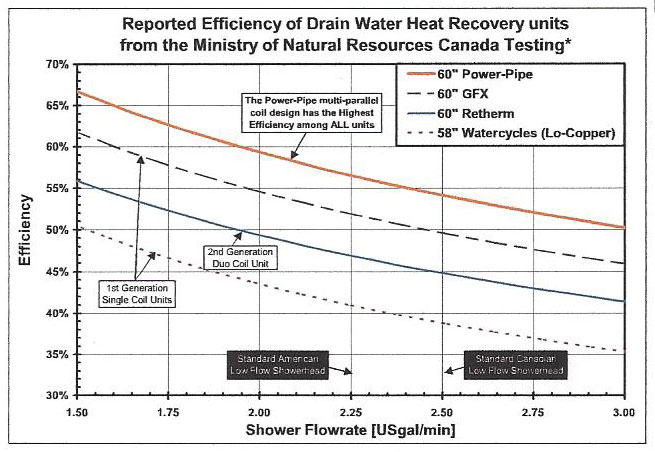

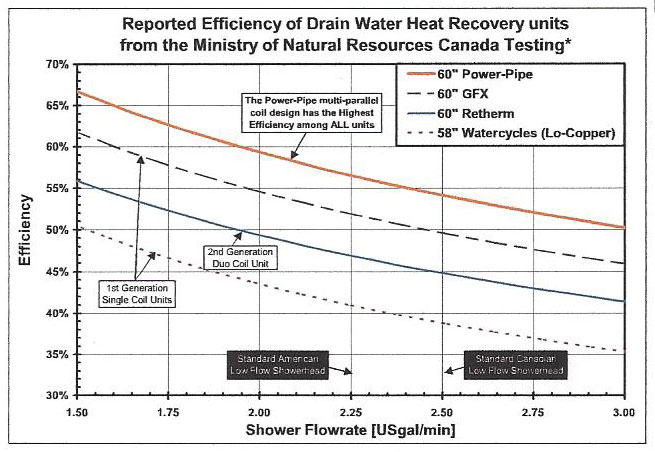

The flow rate and incoming water temperatures affect the return efficiency- higher flow=lower return efficiency, but it's gradual, a logarithmic decline, not a cliff. The NRCAN test is at 2.5 gpm, which isn't a gusher shower, but somewhat higher than the actual flow of most low-flow showerheads. Doubling the flow results in about a 20% reduction in rated return efficiency (eg: a heat exchanger testing at 60% return efficiency @ 2.5 gpm will deliver about 0.8 x 60%= 48% return @ 5 gpm, or 0.8 x 48% = 38% @ 10 gpm.)

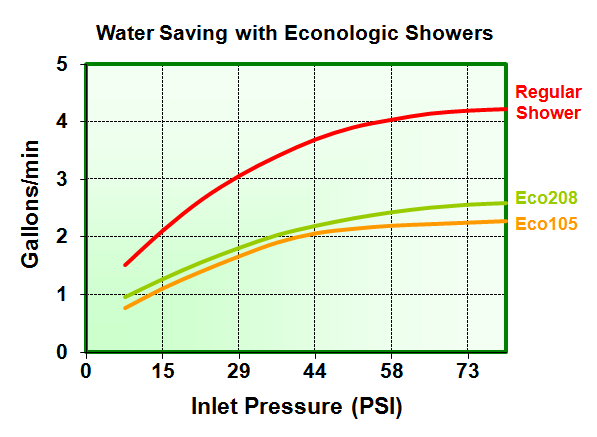

Unless your dynamic (not static) water pressure at the shower is 60psi with all heads flowing (including the hand held) you're probably not really pulling 15 gpm, but you could be pulling 10 if the dynamic pressure drops to something like 25 psi (which it might unless you have 1" or bigger plumbing feeding both the water heater and both the cold & hot runs to the shower). A typical 4gpm showerhead rated at 60 psi delivers about 3 gpm @ 30 psi (dynamic), or 2.5 gpm at 20-25 psi:

Jamming 15 gpm down a heat exchanger may exceed the max flow rating of the heat exchanger (consult the manufacturers), resulting in internal erosion as well as a big pressure drop. If your flows are really that high you'll need to split the flows with a balanced manifold between a pair of heat exchangers (two would be enough for most). Ganging them up is fairly common at commercial laundries or car washes, eg:

(Note- The manifold at the top has to be dead-level to evenly split the drain flows. If going with four it's better to have sub-manifolds splitting to pairs, with an other paired manifold upstream of those, which is what they have done here, though it's a bit hard to see.)

The current best-in class units in terms of return efficiency and lower pressure drop at flow is

EcoDrain's V1000 series, which can be purchased direct from the manufacturer (you have to call them). Renewability's PowerPipe series is currently

distributed in the US through the big orange box store. Similarly, ThermoDrain's TDxxx series

can be purchased online .

They're not cheap, but at 15 gpm x 15 minutes per day a pair of them will pay for themselves pretty quickly on reduced fuel (unless you have your own gas well on your property), and a decent amount up front on reduced water heater capacity requirements.

They buy exactly NOTHING for tub fills or other batch draws. They only work for simultaneous flows, since both the drain and incoming water have to be flowing for the heat exchange to occur.

I was looking at the Phoenix, you think that would work with the drain recovery?

All water heaters can work with drainwater heat recovery, and a Phoenix will easily tolerate 15 gpm flows. The only question is whether a 119 gallon Phoenix has sufficient storage + burner capacity to deliver a 15 minute shower with the (very significant) performance boost added by a heat recovery unit. Drainwater heat recovery is the thermal equivalent of an additional big burner pre-heating the water going to the cold side of the shower and entering the water heater, but it's a burner that uses no gas.

At a 70F temperature rise between the incoming water and the showerheads (35F in coldest part of the winter, 105F at the showerheads) a 15 gpm (x 8.34 lbs/ gallon x 60 minutes= ) ~7500 lbs/hr x 70F= 525,000 BTU/hr. At max fire the output of a 199K condensing burner in the Phoenix covers ~ 190KBTU/hr of the instantaneous flow. If a pair (or a quad) of tall & fat enough drainwater units can recover 40% of the 525K another (0.4 x 525K=) 210K of the flow, which leaves 525K - 190K - 210K= 120KBTU/hr, or (x 15min/60 min)= 30,000 BTU over 15 minutes that would need to be covered by the tank volume. An 80 gallon tank will deliver about 60 gallons (= 500 lbs) of water before it's temp starts to crash. That's enough to support a incoming to outgoing temperature difference of (30K/500lbs=) 60F for 15 minutes, after which the mix has to go more heavily on the hot water, which will then rapidly drop to or below below body temperature. An 80 gallon unit is probably going to be enough, but without sufficient heat exchanger even the 119 gallon Phoenix with a 199K burner won't cut it.

If you can flow test or pressure test the dynamic pressure directly at one of the showerheads when all heads are flowing this napkin analysis sketch can be refined.