cloves

Member

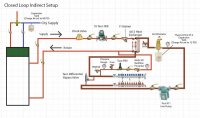

We have a closed radiant heat system and the supply to the pumps was turned off overnight and the thermostats called for heat. The following day when I got home I heard the pumps and they didn't sound right so I shut off the system. I checked the radiant side of the system and it was almost bone dry at one of the outlet valves. I proceeded to evacuate the air out of the system and then tested to see if pumps were still working ( I had flow when thermostats called. I noticed that pressure gauge (On the radiant side), which never has passed 12psi was now running higher 18+. Today I noticed that the #30 pressure valve was going off enough to fill a half bucket of water.

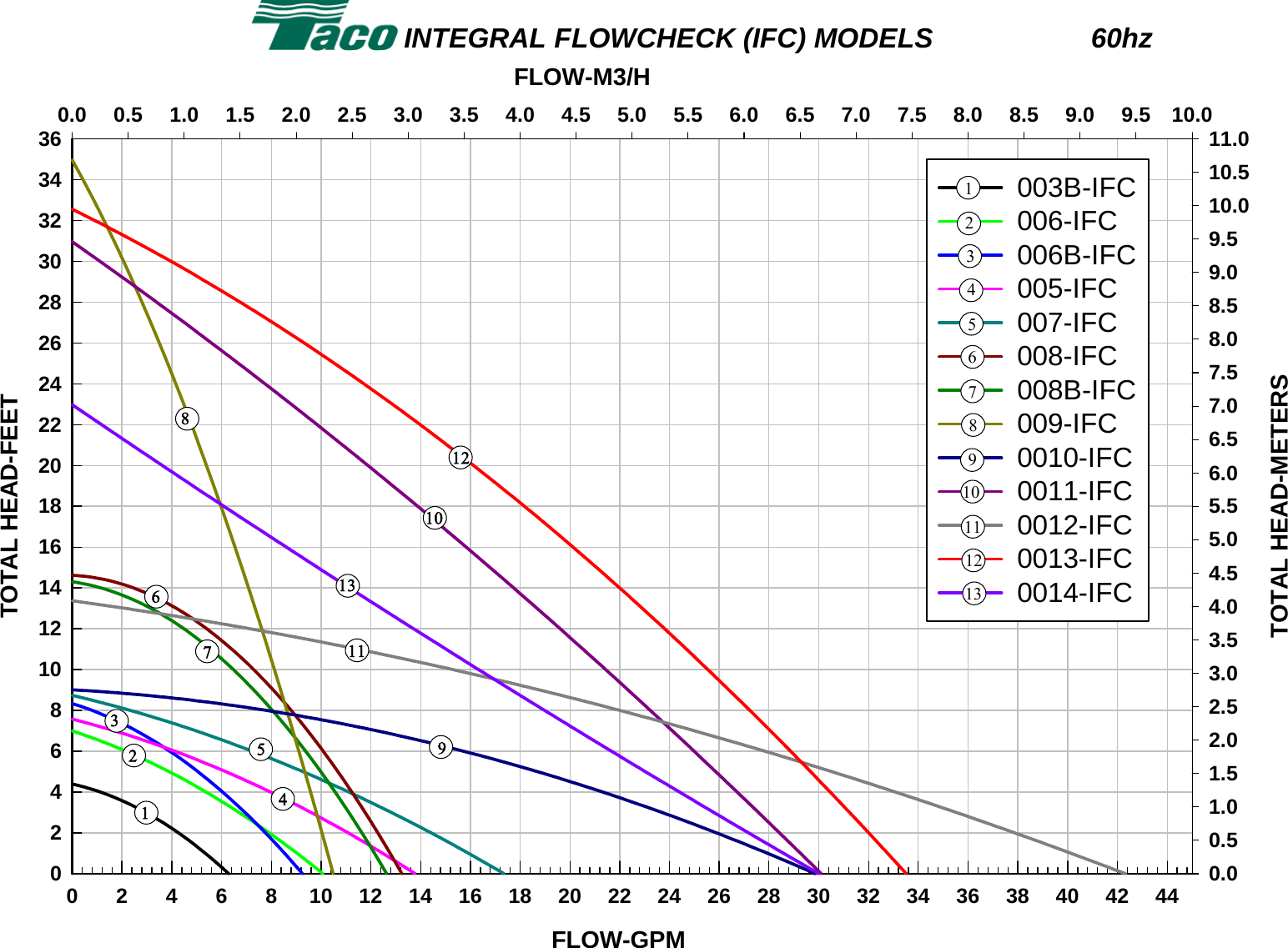

Water supply has been turned back on but something is clearly wrong with the system. We have a Taco 008 SS on the water side and a Taco 011 iron on the radiant side. Yes, they are high head pumps because our radiant guy was a moron who oversized the pumps. But that's a whole other issue.

Anyone have any insight on what could be causing the excessive pressure? The radiant side of the system is the one popping the #30 relief valve. I suspect my Taco 011 is damaged and causing excessive heat but having trouble wrapping my head around the why. The system uses a heat exchanger and since the supply side was the one starving for water not exactly sure if the problem is Taco 008 instead.

Water supply has been turned back on but something is clearly wrong with the system. We have a Taco 008 SS on the water side and a Taco 011 iron on the radiant side. Yes, they are high head pumps because our radiant guy was a moron who oversized the pumps. But that's a whole other issue.

Anyone have any insight on what could be causing the excessive pressure? The radiant side of the system is the one popping the #30 relief valve. I suspect my Taco 011 is damaged and causing excessive heat but having trouble wrapping my head around the why. The system uses a heat exchanger and since the supply side was the one starving for water not exactly sure if the problem is Taco 008 instead.