Chuck

New Member

Howdy folks, new DIYer here from northern NM. This is a great forum that I have been watching for years, now I need a little advice.

I have an adobe home that is currently off the grid and has been since 1999. I am bringing in power to make it a grid-tie system. Being off the grid, I have a 48v system with 8 Rolls batteries and two large inverters. I have 24 panels that charge the batteries and a generator when needed. The house is all standard wiring, running through the inverters. Some systems, like my radiant floor, are a little odd and I need advice to get them converted.

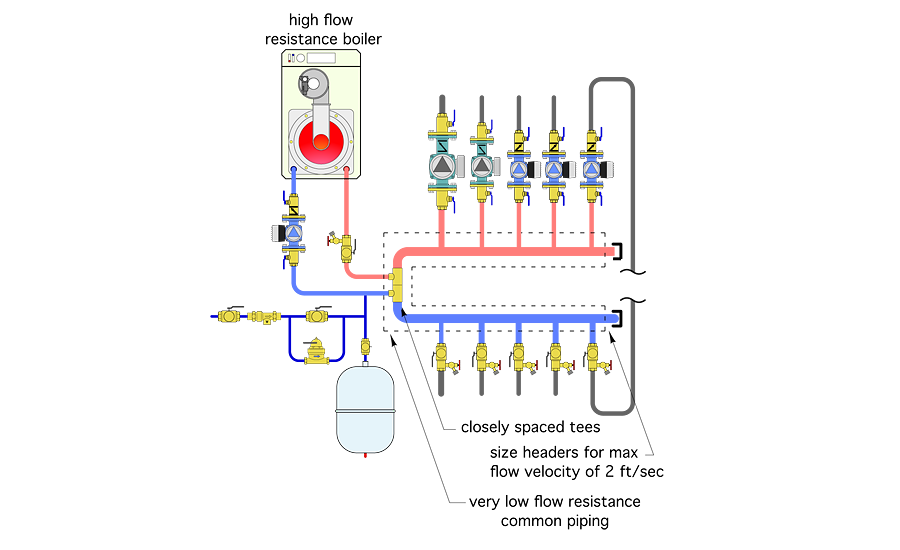

My current radiant floor has 2 circulating pumps, one for the front and one for the back of the house. These are 24volt pumps that barely push 3gpm. The water is heated with a tankless Noritz combi boiler (CB-199-DV-LP) running on propane. I have a weird proprietary system someone installed that turns on the pumps and boiler from the input from the t-stat in the house.

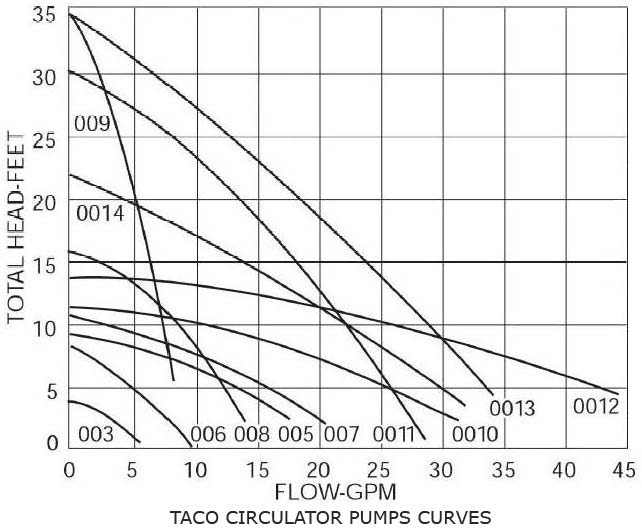

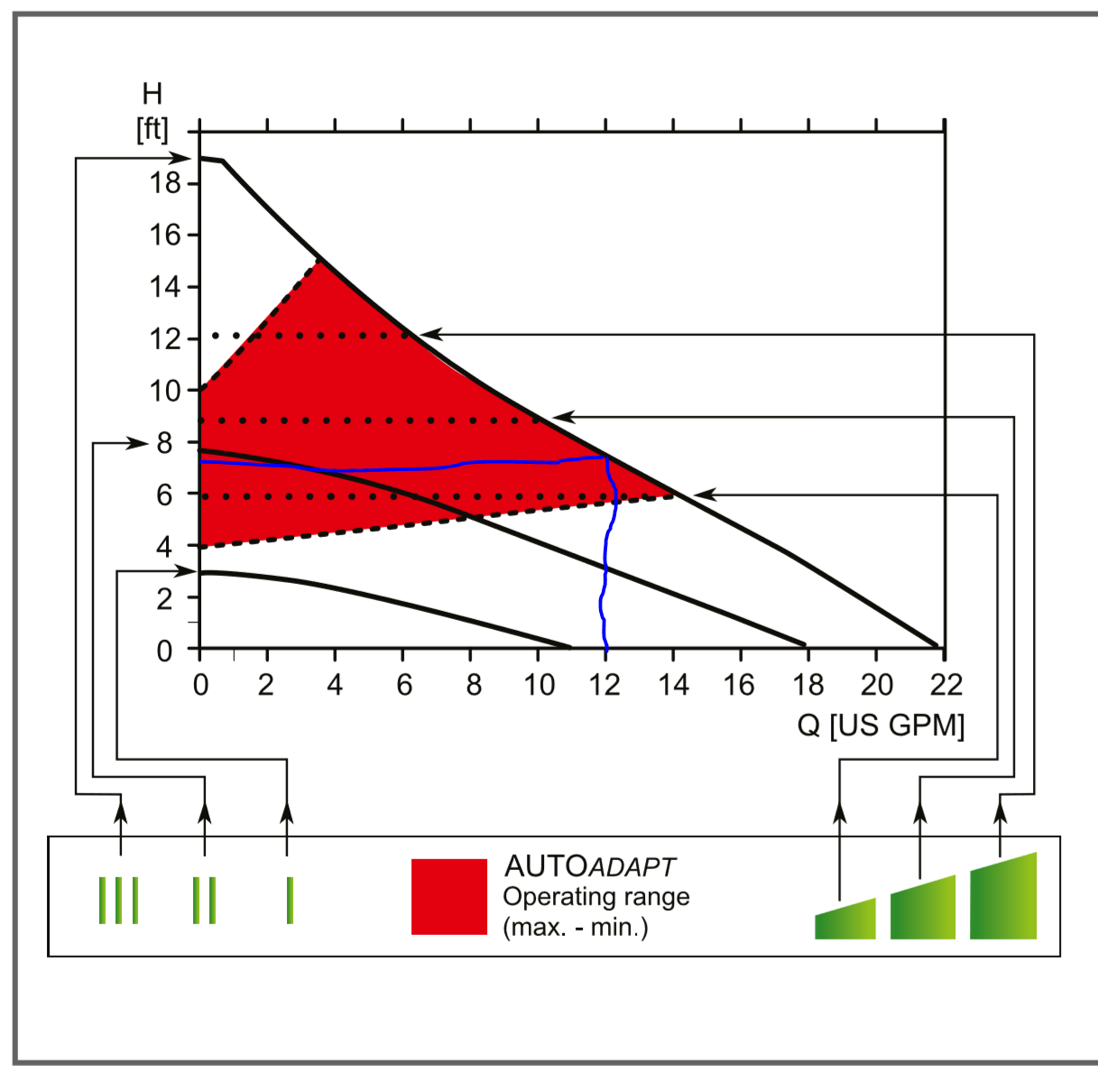

So the 24volt pumps will be going away, replaced with standard 120v pumps. The proprietary wiring goes away. I'll need some sort of pump controller that gets notice from the t-stat to turn on the pumps and let the boiler know to turn on. This is where I need the advice on whether or not I need this pump controller, what kind I need, and whether or not you think a water storage tank would be good to add to the system or not. There are zone valves in the house, but the old wiring is jacked up and I've never used them. The radiant is either on or off for the front and back of the house. To get the zone valves to work would require new t-stat wiring and with adobe that's a pain.

Thanks for any advice. Chuck...

I have an adobe home that is currently off the grid and has been since 1999. I am bringing in power to make it a grid-tie system. Being off the grid, I have a 48v system with 8 Rolls batteries and two large inverters. I have 24 panels that charge the batteries and a generator when needed. The house is all standard wiring, running through the inverters. Some systems, like my radiant floor, are a little odd and I need advice to get them converted.

My current radiant floor has 2 circulating pumps, one for the front and one for the back of the house. These are 24volt pumps that barely push 3gpm. The water is heated with a tankless Noritz combi boiler (CB-199-DV-LP) running on propane. I have a weird proprietary system someone installed that turns on the pumps and boiler from the input from the t-stat in the house.

So the 24volt pumps will be going away, replaced with standard 120v pumps. The proprietary wiring goes away. I'll need some sort of pump controller that gets notice from the t-stat to turn on the pumps and let the boiler know to turn on. This is where I need the advice on whether or not I need this pump controller, what kind I need, and whether or not you think a water storage tank would be good to add to the system or not. There are zone valves in the house, but the old wiring is jacked up and I've never used them. The radiant is either on or off for the front and back of the house. To get the zone valves to work would require new t-stat wiring and with adobe that's a pain.

Thanks for any advice. Chuck...