I'm not sure where to begin with all of the mis-conceptions/anxieties presented here. (Try line breaks/paragraph breaks- it's easier to read.)

In general mod con boilers are more efficient at lower firing rates than at higher rates, but more efficient when modulating than when cycling on/off.

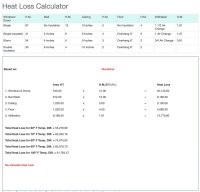

When all of the available data (including online load tools that usually oversize by 25% or more) is pointing to a 99% heat load well under 70K even when using max-leakage assumptions, there is NO risk to going with an 80K boiler, no matter how ludicrously oversized the original boiler was. Even the fuel use estimate came up with only a 61K, even when using unrealisitcally high boiler efficiency on the ancient beast.

A "typical" 2400' uninsulated house + 1200' basement with only single panes would still only run in ~45-55K range, and a 60K boiler would be the "right" boiler. With a bit of air sealing and some fluff in the attic those houses usually duck under 50K.

Manual-J also includes wind factors, which do increase the infiltration rate.

If the house was kept at 70F last December and January it has enough radiation, but even if there weren't enough radiators a bigger boiler won't fix it. If the room radiation is un-balanced with the room loads, oversizing the boiler isn't going to fix that either.

It won't take 12 hours to recover from a 20F drop in indoor temperature even if the boiler is EXACTLY sized for the load at -10F and it's actually -10F outside. The recovery rate is a function of the entire thermal mass of everything in the house and the amount of radiation, not just the burner size. I was out of power for two full days early this winter (again, in a house of comparable size to yours) and most of the house hit 45-50F indoors, and even at ~45,000 BTU/hr (radiation-limited at the water temps I'm running) the house got up to 70F in less than three hours (I think it was less than two, but I wasn't trying to time it.)

Any modulating system should use only high efficiency ECM drive pumps, since the goal is to be pumping at pretty much a 100% duty cycle during most of the heating season. It doesn't take any more pumping power to deliver the heat from a modulating 150K boiler than an 80K boiler- the pumping rates are the same.

An 80K boiler delivers heat at twice the rate of a typical 50 gallon standalone water heater, and can keep up with a continuous shower. By the time you've dried off and dressed the indirect will have recovered. A 120K boiler only cuts that already short recovery time by 1/3 relative to an 80K boiler, so instead of 6 minutes it's only 4. Do you really care about those 2 minutes?

The flue losses are accounted for in the steady state efficiency of the boiler. A 95% efficiency 250K boiler has the same fractional flue losses as 95% efficiency 50K boiler for any given amount of heat delivered.

I've never seen anybody tear out a right sized properly installed mod-con to go back to a cast iron beast, but you have? If you want a cast iron beast you're still better off sizing it to no more than 1.4x the design heat load, so you're looking at something no bigger than 100K-in for even your exaggerated worst-case pre-insulation upgrades scenario, 90K if you follow through with the upgrades.

The type of air sealing I'm referring to isn't something that would require maintenance or "...chasing drafts all winter..." . When you foam-seal the band joist or properly seal the attic floor prior to insulating they don't regain any appreciable leakage for decades. Sealing the top of the house and the bottom of the house have the greatest effects on your overall infiltration load, since that's what defines the stack effect pressures. The band joist and foundation sill usually adds up to more than all window & door crackage combined.

Most professional engineers specify the equipment to the ASHRAE 1.4x multiplier, and if running a careful Manual-J would/could guarantee the performance on a sub-zero day, but maybe not on a -30F day unless you insisted on that ahead of time.

With high mass radiation like high volume cast iron radiators going with a right sized boiler isn't going to save you 100 bucks a year since even a 120K boiler isn't going to short-cycle, but the smaller boiler is likely to improve comfort and the longevity of the equipment due to fewer (but longer) burn cycles, etc. Installed & sized correctly a stainless steel mod-con should be good for at least 20 years (not 10-15), even though the warranty may only be for 10.

Even using crappy rules-of-thumb sizing the "analysis-challenged" hacks in my area (which has comparable design temps to yours) use for sizing boilers they tend to go with 35 BTU per square foot of conditioned space for uninsulated houses like yours, which would put you in a 100K-in cast iron boiler, not a 120K condensing boiler. The same guys use 25 BTU per foot if it has storm windows and some fluff in the attic, which would would be a 70K-in cast iron boiler.

You took the time to run the math using US Boiler's simplified (and well padded) load tool using conservative rather than aggressive assumptions as if it were the crummiest house in the Hudson Valley (which it probably isn't). So why don't you believe the math?

Even with the errors all skewed to the high side?

The tool-derived 74KBTU/hr load at -10F (the 80F temperature difference) is still only an 80K condensing boiler.

And -10F is 12F colder than your

actual 99% design temp.

The first 10-15K of load is pretty cheap and easy to peel off on the first round when weatherizing a house like yours. An 80K boiler is arguably oversized for the load of the "after" picture if you're eventually taking it all the way with wall insulation, foundation insulation, better windows, etc, and a 50K boiler would probably probably more appropriate than an 80K boiler on the "...the next round...".

In 20 years there may indeed be reversible hydronic chillers capable of handling the new-improved lower load using the same radiation for heating using wind (grid) power, but I'm not placing any bets on that just yet. CO2-refrigerant compressors can deliver 140F water pretty efficiently from air coils at -10F outdoor temps, but they require bigger delta-Ts on the water loop than you're likely to get. R410A heat pumps can do it too but at lower efficiency. R410A is probably going away by then but there are other refrigerants, other approaches. Depending on where your "after all upgrades" load comes out you could probably get there with a 3-4 ton ground source heat pump with the existing radiation.

Dandelion hasn't released the specs on their hydronic output version (currently under development), but they're marketing their

ducted air lineup pretty aggressively in your neighborhood.