WV Bob

Member

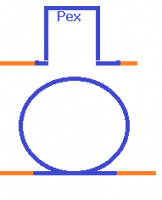

I've got a leaking 1/2" copper supply line that I've been trying to fix with Sharkbites and PEX. The problem I've run into is the copper line is basically fixed in place so there's no "wiggle room" to fit the PEX in after allowing for the Sharkbite installation depth. What I end up with is on one end, copper-Sharkbite-PEX and on the other copper-Sharkbite and I can't get the PEX in the fitting.

Is there a certain order I should be doing this in? Can anyone offer any tips to get me through this dilemma? I hope this is something that has a common solution.

Thanks,

Bob

Huntington, WC

Is there a certain order I should be doing this in? Can anyone offer any tips to get me through this dilemma? I hope this is something that has a common solution.

Thanks,

Bob

Huntington, WC