preppypyro

New Member

Type of pump?

Submersible pump is a 3/4 berkly

Three wire (control box) 3 wire with ground

Wire Size unsure

Wire Length approx 350 feet from house, 100 feet down well

Size of Pump?

Motor Horsepower? 3/4

Pump Model #unsure

Date Pump Installed in november of 2007

Pumping from?

Water Well

Depth of well 180 feet, pump is at 100 feet

Depth to water approx 10 feet from the top of the well

Pump Setting__________

Pipe Size 1 and 1/4 inch from well to the house

Drop Pipe Material

plastic poly water pipe 1 and 1/4 down the well, and from the well to the house

Well Recovery Rate 12 gpm

Well Casing Diameter 5 inchs inner diameter

Rock Well__________ Sand Well__________ Other______________

Date Well Drilled August of 2007

Well Casing Material

PVC

Pressure Tank?

Bladder or diaphragm tank (one pipe to tank)

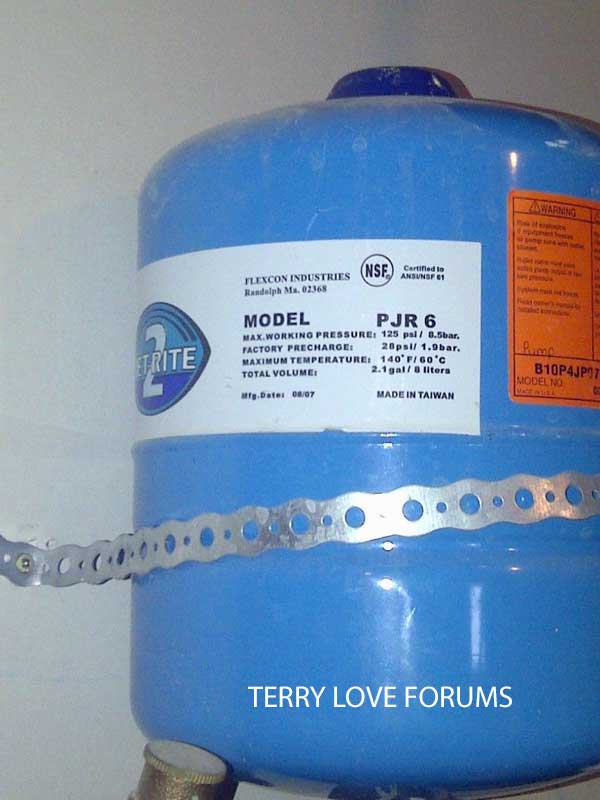

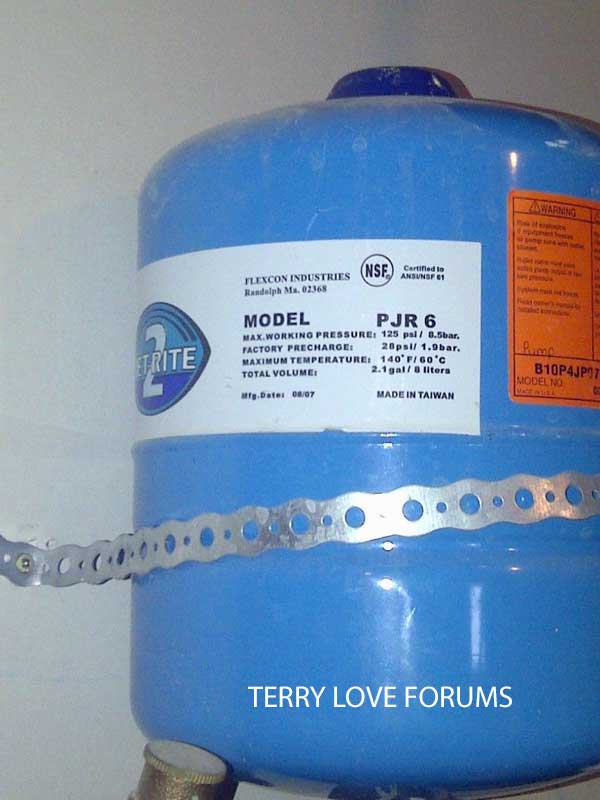

Model of tank is jet rite 2, model pjr 6 2.1 gallon tank

Air charge in top of tank, with pump off and water drained 30 PSI

Pressure Switch Setting? We have an adjustable switch, believe it is set at just over 50 psi, not sure how to tell what the "on" setting is.

Pump Control Method?

Franklin Electric Mono Drive

Pump Protection "unsure"

Cycle Sensor_________

Pumptec_____________

Low pressure cutoff switch (lever on side)__________

Other_______________

Filters or Softeners culligan iron filter first in line, culligan water softener next in line, after the pressure tank

Water Used For?

House Use, 2 adults, one 6 month old. Three bathrooms, two showers and one shower/bath, I have a multimeter, and know a little how to use it.

Questions I have.

Ok first post here! I have done a lot of reading here, decided to join and add/contribute (IF I ever can!)

Little background. I live outside of Saskatoon, Saskatchewan, Canada. Not sure exactly what the frost level is, but we bury our stuff at minimum of 6 feet underground, personally I buried all my septic and water lines at 8 feet.

I have a 5 inch (inner diamter) well, and installed the pitless adapter at just shy of 8 feet. We got some poor advice when we first installed in back in 07, and didnt use a brass fitting from the pitless to the barbed hose adapter, so we developed a leak, and had to dig it up two days ago and repair it.

The first question I have is regarding water line routing. When we first dug the line, we had the line going as straight as we could, with the only turn in the line being very gradual. The other night when we were repairing the problem, we rushed and installed a joiner in the water pipe, and created a loop underground before it attached back to the pitless.

I will be the first to admit that it was late at night and my wife and I were both tired, and just wanted to finish, so we took the easy route, but I was wondering if the loop underground (think of a loop maybe 3 feet in diameter) would hurt anything, like water pressure? We were careful when we buried it, and it shouldn't rub or anything, but it did get me thinking about a possible loss in pressure, perhaps??

Second question is involving my pressure system itself.

Attached is the way I have my system set up currently

I have one of these for a switch, and its adjustable with a Allan wrench up top.

This is the specs on the tank we have.

Ok so now my question! I was fiddling around with that switch when the water was turned off, and moved it from the factory setting of 50. I fiddled with it more when the water was back on, and have it sitting at almost 55 psi on the guage. I checked the tank pressure with the water off and it was at 30 psi.

From a chart I had found, and some quick calculations, I believe my pressure tank should be pumped up to about 38 psi.

Is it just that easy? Just take my compressor and fill it up to 38 with the water turned off (and a tap open, don't do anything till all the water comes out, then fill the tank)

Say i wanted to boost my pressure in my house up a little more, say to 60. Would I just need to adjust the switch with the allan key, let my system drain, fill up the pressure tank to 42ish psi, then all is goods? Any reason to not bump it up a little bit? (like from 50-60?) Since I have the constant pressure system, maybe I need to stay within some certain values?

(I realize the cycle stop valves are popular in here, but the mono drive is what i have for now!)

Sorry for the long first post, and I'm sure probably silly questions to many of you!

Thanks for any advice, replies, and any help you guys can provide.

Submersible pump is a 3/4 berkly

Three wire (control box) 3 wire with ground

Wire Size unsure

Wire Length approx 350 feet from house, 100 feet down well

Size of Pump?

Motor Horsepower? 3/4

Pump Model #unsure

Date Pump Installed in november of 2007

Pumping from?

Water Well

Depth of well 180 feet, pump is at 100 feet

Depth to water approx 10 feet from the top of the well

Pump Setting__________

Pipe Size 1 and 1/4 inch from well to the house

Drop Pipe Material

plastic poly water pipe 1 and 1/4 down the well, and from the well to the house

Well Recovery Rate 12 gpm

Well Casing Diameter 5 inchs inner diameter

Rock Well__________ Sand Well__________ Other______________

Date Well Drilled August of 2007

Well Casing Material

PVC

Pressure Tank?

Bladder or diaphragm tank (one pipe to tank)

Model of tank is jet rite 2, model pjr 6 2.1 gallon tank

Air charge in top of tank, with pump off and water drained 30 PSI

Pressure Switch Setting? We have an adjustable switch, believe it is set at just over 50 psi, not sure how to tell what the "on" setting is.

Pump Control Method?

Franklin Electric Mono Drive

Pump Protection "unsure"

Cycle Sensor_________

Pumptec_____________

Low pressure cutoff switch (lever on side)__________

Other_______________

Filters or Softeners culligan iron filter first in line, culligan water softener next in line, after the pressure tank

Water Used For?

House Use, 2 adults, one 6 month old. Three bathrooms, two showers and one shower/bath, I have a multimeter, and know a little how to use it.

Questions I have.

Ok first post here! I have done a lot of reading here, decided to join and add/contribute (IF I ever can!)

Little background. I live outside of Saskatoon, Saskatchewan, Canada. Not sure exactly what the frost level is, but we bury our stuff at minimum of 6 feet underground, personally I buried all my septic and water lines at 8 feet.

I have a 5 inch (inner diamter) well, and installed the pitless adapter at just shy of 8 feet. We got some poor advice when we first installed in back in 07, and didnt use a brass fitting from the pitless to the barbed hose adapter, so we developed a leak, and had to dig it up two days ago and repair it.

The first question I have is regarding water line routing. When we first dug the line, we had the line going as straight as we could, with the only turn in the line being very gradual. The other night when we were repairing the problem, we rushed and installed a joiner in the water pipe, and created a loop underground before it attached back to the pitless.

I will be the first to admit that it was late at night and my wife and I were both tired, and just wanted to finish, so we took the easy route, but I was wondering if the loop underground (think of a loop maybe 3 feet in diameter) would hurt anything, like water pressure? We were careful when we buried it, and it shouldn't rub or anything, but it did get me thinking about a possible loss in pressure, perhaps??

Second question is involving my pressure system itself.

Attached is the way I have my system set up currently

I have one of these for a switch, and its adjustable with a Allan wrench up top.

This is the specs on the tank we have.

Ok so now my question! I was fiddling around with that switch when the water was turned off, and moved it from the factory setting of 50. I fiddled with it more when the water was back on, and have it sitting at almost 55 psi on the guage. I checked the tank pressure with the water off and it was at 30 psi.

From a chart I had found, and some quick calculations, I believe my pressure tank should be pumped up to about 38 psi.

Is it just that easy? Just take my compressor and fill it up to 38 with the water turned off (and a tap open, don't do anything till all the water comes out, then fill the tank)

Say i wanted to boost my pressure in my house up a little more, say to 60. Would I just need to adjust the switch with the allan key, let my system drain, fill up the pressure tank to 42ish psi, then all is goods? Any reason to not bump it up a little bit? (like from 50-60?) Since I have the constant pressure system, maybe I need to stay within some certain values?

(I realize the cycle stop valves are popular in here, but the mono drive is what i have for now!)

Sorry for the long first post, and I'm sure probably silly questions to many of you!

Thanks for any advice, replies, and any help you guys can provide.

Last edited by a moderator: