I have recently begun to remodel a storage space and 1/2 bath into a full bath. The storage space comes from my garage, which was 6" below the existing living space height. Drain lines to connect with existing septic tank drains were run via cutting channels in the storage area floor and the pouring concrete to make new floor continuous with existing living space. However, the shower were were creating is a true no-curb walk in with the floor already 1.5" lower so as to use a pre-sloped shower pan with a linear drain on one end. The issue is that in order to connect to the existing drain lines and maintain proper slope for drainage, the height of the shower trap and trunk line to vent and further drainage was basically right at the height of the lowered concrete section for the shower. It ended up being about 1/2" above the height of the floor, because of some connection issues further down the line that couldn't be avoided.

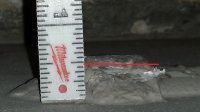

So now I have a 2 foot length of pvc that is protruding in basically the center of the shower about 1/2", and then sloping down to flush with floor at the edge of the shower wall. This will be covered by the pre-sloped shower pan, but only if I carve out a hemispherical length of foam from the bottom of the pan to fit over this protrusion.

My question is: in order to minimize the amount of foam I have to remove from the bottom of the pan (and not worry about cutting through the top of the pan), can I use a grinder or sander and mill off the top of the shower trap drain pipe hub which adds about 3/16" of height over and above the 1/2" of the pipe run itself? And if so, can I use additional pvc cement or epoxy or whatever to seal this sliced area and seal it against leaks later on?

I know that this whole thing is not ideal, but I cannot fix the pipes and still get slope for drainage, so I am stuck with the pipe protruding slightly. Since it is not pressurized, and the top is the only part protruding, my hope is that glue or whatever will keep any water that might collect up to that height during shower usage still inside the pipe, and I can use this pan effectively. What do you guys think?

So now I have a 2 foot length of pvc that is protruding in basically the center of the shower about 1/2", and then sloping down to flush with floor at the edge of the shower wall. This will be covered by the pre-sloped shower pan, but only if I carve out a hemispherical length of foam from the bottom of the pan to fit over this protrusion.

My question is: in order to minimize the amount of foam I have to remove from the bottom of the pan (and not worry about cutting through the top of the pan), can I use a grinder or sander and mill off the top of the shower trap drain pipe hub which adds about 3/16" of height over and above the 1/2" of the pipe run itself? And if so, can I use additional pvc cement or epoxy or whatever to seal this sliced area and seal it against leaks later on?

I know that this whole thing is not ideal, but I cannot fix the pipes and still get slope for drainage, so I am stuck with the pipe protruding slightly. Since it is not pressurized, and the top is the only part protruding, my hope is that glue or whatever will keep any water that might collect up to that height during shower usage still inside the pipe, and I can use this pan effectively. What do you guys think?