Titan7

Member

- Messages

- 39

- Reaction score

- 0

- Points

- 6

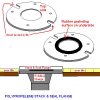

Right now the top of my 4" ABS drain pipe is level with the top of the new subfloor. Tile installer said the top of the finished floor should be 3/4" higher.

thin-set+1/4" hardy backer=3/16" + 3/16" thinset + 3/8" tile =3/4"

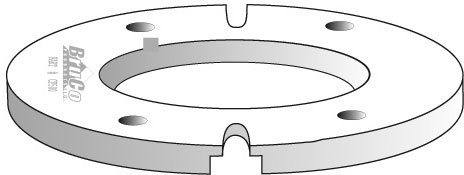

Rather than drill through the tile to mount the closet flange I am going to make a ring spacer out of 3/4" plywood that will fit very closely around the 4" AbS drain, mount that to the subfloor, and have the installer tile around it. I can then glue the flange in and drill the screws into the wood to set it.

Reason I was asking about the floor is I am trying to figure out the closet flange. Right now the top of my 4" ABS drain pipe is level with the top of the new subfloor. The plywood donut, would be the same diameter as the metal ring of the new flange.

Is there any drawback to doing this vs tiling up to the 4"abs and then gluing on the new flange, and then drilling through the tile to mount to the sub floor?

It just seem to me drilling the hard tile has the potential to crack it. I could not see a down side to what I was proposing above.

I plan to use the Oatey glue on flange with a stainless steel ring. I have another with aluminum too, I guess both will work.

thin-set+1/4" hardy backer=3/16" + 3/16" thinset + 3/8" tile =3/4"

Rather than drill through the tile to mount the closet flange I am going to make a ring spacer out of 3/4" plywood that will fit very closely around the 4" AbS drain, mount that to the subfloor, and have the installer tile around it. I can then glue the flange in and drill the screws into the wood to set it.

Reason I was asking about the floor is I am trying to figure out the closet flange. Right now the top of my 4" ABS drain pipe is level with the top of the new subfloor. The plywood donut, would be the same diameter as the metal ring of the new flange.

Is there any drawback to doing this vs tiling up to the 4"abs and then gluing on the new flange, and then drilling through the tile to mount to the sub floor?

It just seem to me drilling the hard tile has the potential to crack it. I could not see a down side to what I was proposing above.

I plan to use the Oatey glue on flange with a stainless steel ring. I have another with aluminum too, I guess both will work.