KP Texan

Marine Engineer

I've followed this forum for awhile now and from things I've learned here and other places around the net I decided to attempt to solder my own water stop valves beneath my kitchen sink. The previous valves weren't doing too well; one of them leaked through the outlet when shut off and the outlet on the other one would not properly seal properly with a stainless braided flexible hose that used an internal brass compression fitting (rather than rubber). These valves were also attached to the copper stub outs using compression fittings. Once those fittings were cut off, it did not leave me much room for error with another compression fitting so that's another reason I decided to try my hand at soldering some new valves on. I purchased a Bernzomatic TS8000 torch with MAPP gas, various copper fittings, some Keeney quarter turn valves, some wire cleaning brushes, and a Lenox kit that included some Sterling flux and solder. Everything seemed to go well with the soldering; I made sure to properly clean all joints inside/out, flux both parts, and heat the joint so that the solder would flow towards the heat while being careful not to overheat (that Mapp gas heats pretty quick!). Here's my question: how long should I carefully watch these joints for signs of leakage? Although I'm pretty handy and have done some welding and soldering, this is my first time to sweat copper pipe so I'm sort of skeptical of the quality. Do these joints typically develop pinhole leaks first or do they catastrophically fail and tend to cause flooding?? It never freezes here so I don't really have to worry about stresses other than standard water pressure.

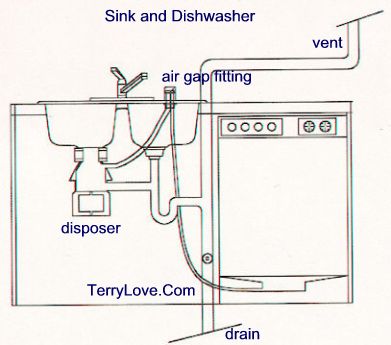

My other question relates to the configuration of my under sink drain piping. My garbage disposer went out and I purchased a new one. The new disposer had a down turned outlet rather than a straight pipe coming out like the old one. I now have two P-traps; one from the disposer and one from the other sink bowl. Will this pass code? Please see attached pics.

Thanks so much,

Wes

My other question relates to the configuration of my under sink drain piping. My garbage disposer went out and I purchased a new one. The new disposer had a down turned outlet rather than a straight pipe coming out like the old one. I now have two P-traps; one from the disposer and one from the other sink bowl. Will this pass code? Please see attached pics.

Thanks so much,

Wes

Last edited by a moderator: