Shoes

New Member

Hey there -

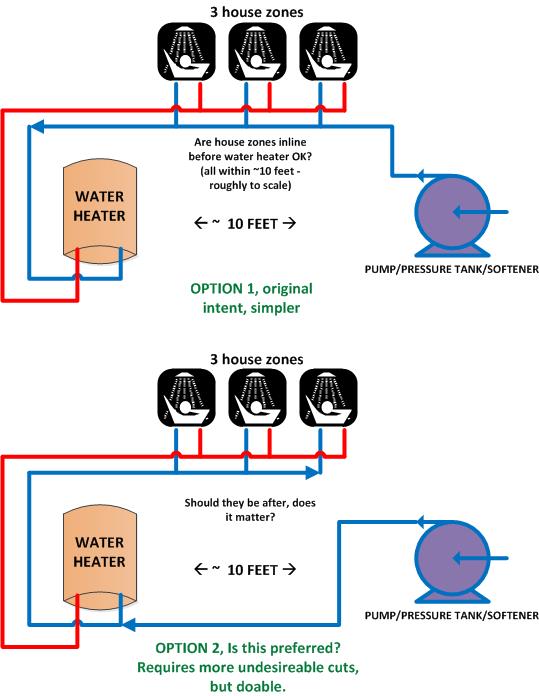

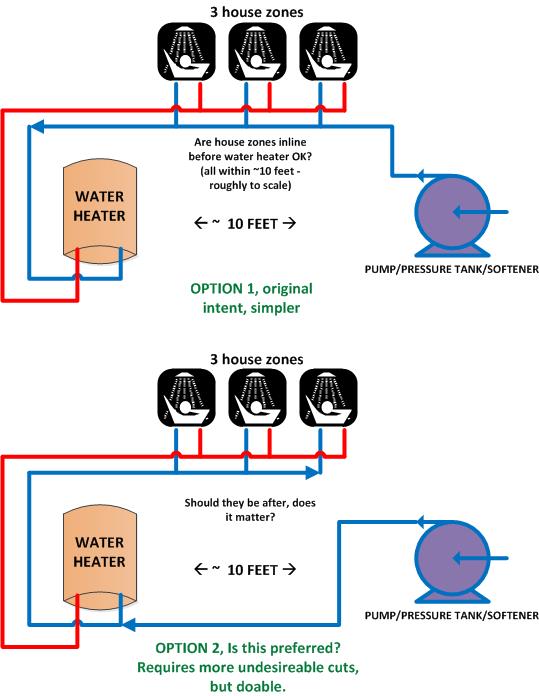

I am running new plumbing to replace PB. I am bringing 3 house zones together between the water heater and supply line. My original intent was to have cold supply breaking off to the house zones on its way to the water heater 10 feet away (diagram attached). But then I began to wonder if it is not preferable to have the water heater last in this series? Is it bad to have the water heater sequentially *after* the house zones? Should the heater be first? Maybe it doesnt matter - but I wanted to ask the experts. I'd prefer to go with the original design as it would require less re-work with the water heater and be visually cleaner. But I'll do what I need to if there is reason.

So - looking at the attached image, is it ok to have the water heater last in the series? Or should it be first instead, making the house zone manifold last (option 2)?

Thoughts? Thanks for the help.

I am running new plumbing to replace PB. I am bringing 3 house zones together between the water heater and supply line. My original intent was to have cold supply breaking off to the house zones on its way to the water heater 10 feet away (diagram attached). But then I began to wonder if it is not preferable to have the water heater last in this series? Is it bad to have the water heater sequentially *after* the house zones? Should the heater be first? Maybe it doesnt matter - but I wanted to ask the experts. I'd prefer to go with the original design as it would require less re-work with the water heater and be visually cleaner. But I'll do what I need to if there is reason.

So - looking at the attached image, is it ok to have the water heater last in the series? Or should it be first instead, making the house zone manifold last (option 2)?

Thoughts? Thanks for the help.