Blitzen

New Member

What a great forum!

I have looked through the old and the new forum for an answer and did not find one that quite fit my problem.

The specs on my well are:

Goulds

2 HP

Well:

138 ft

14.5 Gal. Per Minute

13 ft drawdown after 4 hours

300 feet of 1.5 inch pipe to pressure tank.

10 gauge wire to the pump from the tank

Dug in 2003.

The problem is that after using 50 gallons of water or so my well pump will suddenly shut off. I will then disconnect the connections by way of the pressure switch, count to 15 and reconnect and water starts flowing again. When this starts to happen I get less and less water before the pump cuts out.

-I have tested the voltage at the pressure switch and there is current going to the pump.

-I have pressured up the system to 50psi and turned off the electrical and the output pipe from the pressure tank for a week at a time and it is still at 50 when I return so there seems to be no leak down from the pressure tank.

- I have replaced pressure switches

Is the pump over heating?

Is it having to push too much water through the 1.5 pipe to far for the pressure tank?

Thanks for any ideas!

Blitzen

I have looked through the old and the new forum for an answer and did not find one that quite fit my problem.

The specs on my well are:

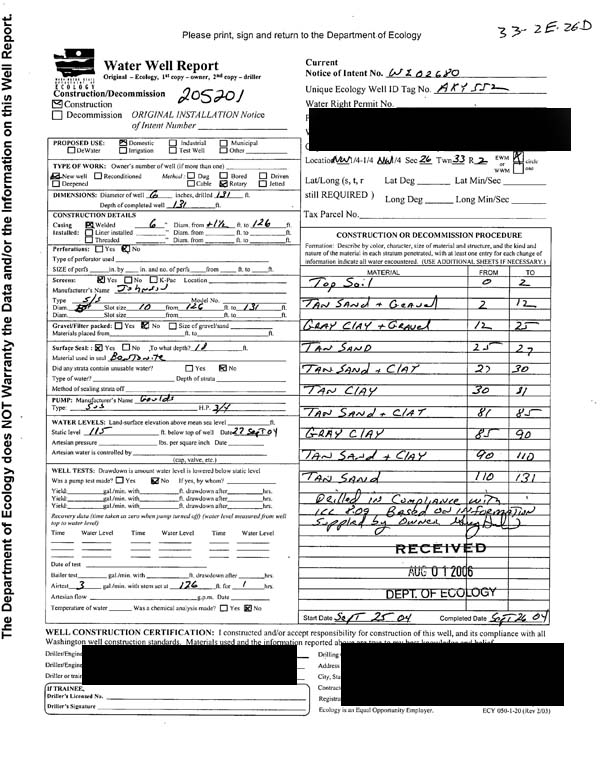

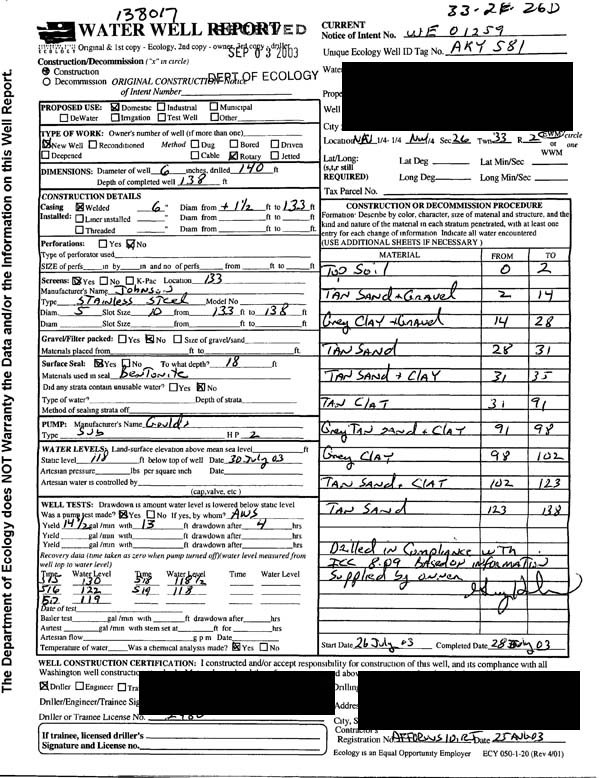

Goulds

2 HP

Well:

138 ft

14.5 Gal. Per Minute

13 ft drawdown after 4 hours

300 feet of 1.5 inch pipe to pressure tank.

10 gauge wire to the pump from the tank

Dug in 2003.

The problem is that after using 50 gallons of water or so my well pump will suddenly shut off. I will then disconnect the connections by way of the pressure switch, count to 15 and reconnect and water starts flowing again. When this starts to happen I get less and less water before the pump cuts out.

-I have tested the voltage at the pressure switch and there is current going to the pump.

-I have pressured up the system to 50psi and turned off the electrical and the output pipe from the pressure tank for a week at a time and it is still at 50 when I return so there seems to be no leak down from the pressure tank.

- I have replaced pressure switches

Is the pump over heating?

Is it having to push too much water through the 1.5 pipe to far for the pressure tank?

Thanks for any ideas!

Blitzen