iconoclast hero

New Member

There's a 2012 GE HW tank in the basement, somewhat central to the original ranch structure.

Adding bath to existing addition with potential future expansion f/mud room & garage.

Ran 1" PEX to bath while picking up existing kitchen hot along the way.

A 1/2" PEX dedicated return line connects up with the 1" PEX at the end of the run (new bath) as well as at a bypass valve located past the kitchen where the addition shutoffs are located.

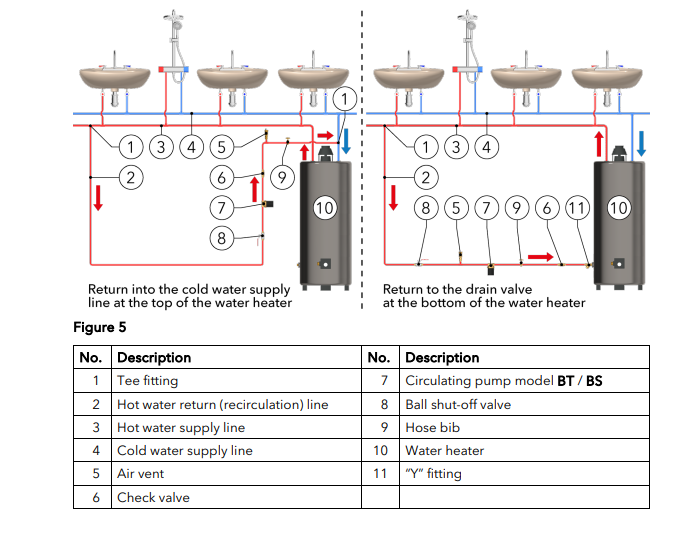

I followed the right side of this this diagram from Bell & Gossett, but considering the age of the HW tank and the likelihood that the replacement tankless water heater will have a built in pump, the HO and I decided to skimp on the pump ($35 Vevor pump from Amazon Warehouse—THD and Lowe's both sell that pump btw...):

(I'm unsure whether it is worth cutting in an 1/8" MPT radiator valve on a tee, and if so, where, but it is ready to go.)

Here's the string of brass and the pump:

(That bleeder valve's on the floor in the top left of the picture.)

Anyway, 1" PEX out, 1/2" PEX back. Effectively the bypass has been open and the addition off as the latter's still under construction. I figured out yesterday that I have a gravity loop I had not intended ... which I want to stop before summer arrives.

How?

Adding bath to existing addition with potential future expansion f/mud room & garage.

Ran 1" PEX to bath while picking up existing kitchen hot along the way.

A 1/2" PEX dedicated return line connects up with the 1" PEX at the end of the run (new bath) as well as at a bypass valve located past the kitchen where the addition shutoffs are located.

I followed the right side of this this diagram from Bell & Gossett, but considering the age of the HW tank and the likelihood that the replacement tankless water heater will have a built in pump, the HO and I decided to skimp on the pump ($35 Vevor pump from Amazon Warehouse—THD and Lowe's both sell that pump btw...):

(I'm unsure whether it is worth cutting in an 1/8" MPT radiator valve on a tee, and if so, where, but it is ready to go.)

Here's the string of brass and the pump:

(That bleeder valve's on the floor in the top left of the picture.)

Anyway, 1" PEX out, 1/2" PEX back. Effectively the bypass has been open and the addition off as the latter's still under construction. I figured out yesterday that I have a gravity loop I had not intended ... which I want to stop before summer arrives.

How?