stern_howie

New Member

- Messages

- 5

- Reaction score

- 0

- Points

- 0

Hello,

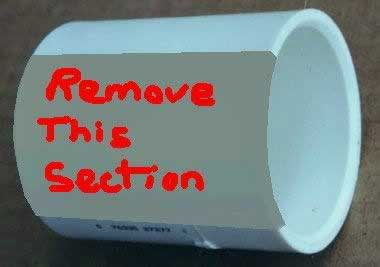

A Clogged toilet toilet (now clear) has brought me to a spot in the wall downstairs where upon removing a piece of drywall exposes a screw through the 3" ABS pipe.

I picked up a 3" coupling but before I do any cutting etc. I am looking for any tips. Obviously fitting a coupling to pipes before they are installed is a lot easier than installing in to a pipe already in place.

I don't think the pipe has got much play from side-to-side....I've put together ABS before so I am familiar with the adhesive etc. it's the cutting of the pipe to fit the coupling I am stuck on.

thanks for any help.

A Clogged toilet toilet (now clear) has brought me to a spot in the wall downstairs where upon removing a piece of drywall exposes a screw through the 3" ABS pipe.

I picked up a 3" coupling but before I do any cutting etc. I am looking for any tips. Obviously fitting a coupling to pipes before they are installed is a lot easier than installing in to a pipe already in place.

I don't think the pipe has got much play from side-to-side....I've put together ABS before so I am familiar with the adhesive etc. it's the cutting of the pipe to fit the coupling I am stuck on.

thanks for any help.