waefish

New Member

Hi Terry,

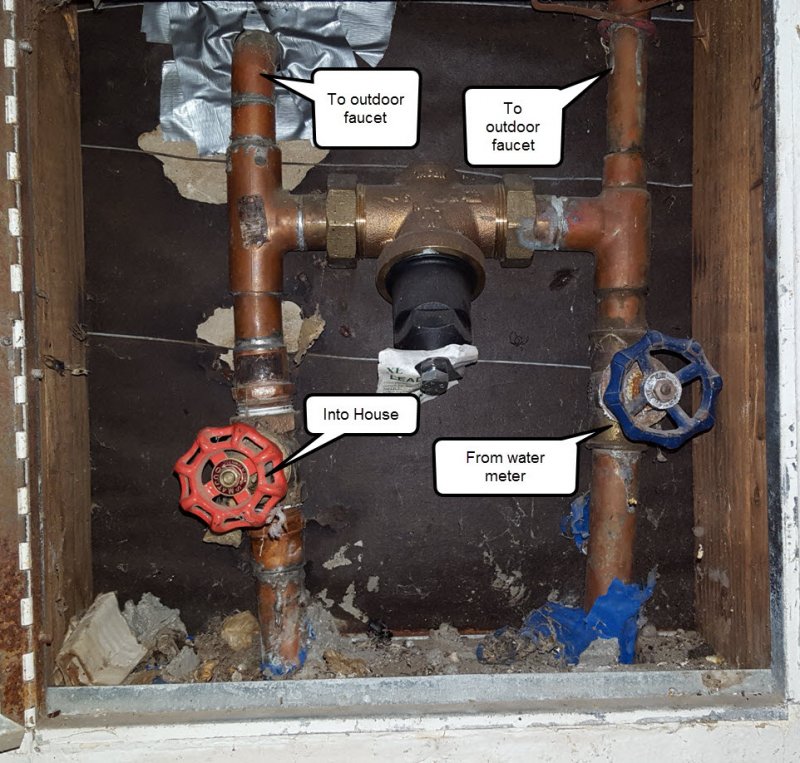

I need to replace two gate valves in my home. One valve is locked up, and the other appears to have a broken stem. The regulator can be remove but there is no play in the pipes that will allow me to separate and reconnect the joints. The two pipes that feed outdoor faucets exit to the outside through the stucco wall and have no play in them. behind the valves is the back side of a stucco wall and there is very little space between the valves and the wall maybe 1/4 inch.

My question is how do I remove the old valves when there is no play in the pipes to separate the joints. I could cut one or more of the copper pipes but there's still no movement in the pipes that will allow me to put it back together.

How would a professional complete this replacement?

Thanks for your advise.

Wayne

I need to replace two gate valves in my home. One valve is locked up, and the other appears to have a broken stem. The regulator can be remove but there is no play in the pipes that will allow me to separate and reconnect the joints. The two pipes that feed outdoor faucets exit to the outside through the stucco wall and have no play in them. behind the valves is the back side of a stucco wall and there is very little space between the valves and the wall maybe 1/4 inch.

My question is how do I remove the old valves when there is no play in the pipes to separate the joints. I could cut one or more of the copper pipes but there's still no movement in the pipes that will allow me to put it back together.

How would a professional complete this replacement?

Thanks for your advise.

Wayne