Help / advice please:

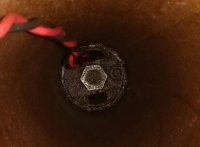

The attached picture is looking down my 6" steel casing well. Drilled in 1978+/-.

The "seal" is about 4-5 feet down. Obviously, I have no clue but it does not look like a well seal as nothing is sealed. The oval holes look to be just that - holes.

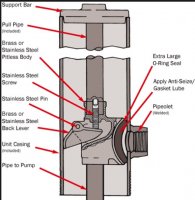

My pump needs replaced and a local driller came to remove the pump.

He screwed into the female threads in the center and pulled with his rig. When pulling (he said 12K lbs force) the pull pipe broke off at the top.

He suggested we soak with PB blaster for a few days and he will return tomorrow. He says if he pulls again and it doesn't come up, we need to drill a new well.

I have soaked it for a few days, but upon further revue, I'm having second thoughts and figure there has to be a way to remove the "whatever it is."

Any education and advice is very appreciated.

Thanks,

Rob

The attached picture is looking down my 6" steel casing well. Drilled in 1978+/-.

The "seal" is about 4-5 feet down. Obviously, I have no clue but it does not look like a well seal as nothing is sealed. The oval holes look to be just that - holes.

My pump needs replaced and a local driller came to remove the pump.

He screwed into the female threads in the center and pulled with his rig. When pulling (he said 12K lbs force) the pull pipe broke off at the top.

He suggested we soak with PB blaster for a few days and he will return tomorrow. He says if he pulls again and it doesn't come up, we need to drill a new well.

I have soaked it for a few days, but upon further revue, I'm having second thoughts and figure there has to be a way to remove the "whatever it is."

Any education and advice is very appreciated.

Thanks,

Rob