Dave 1804

New Member

Hello,

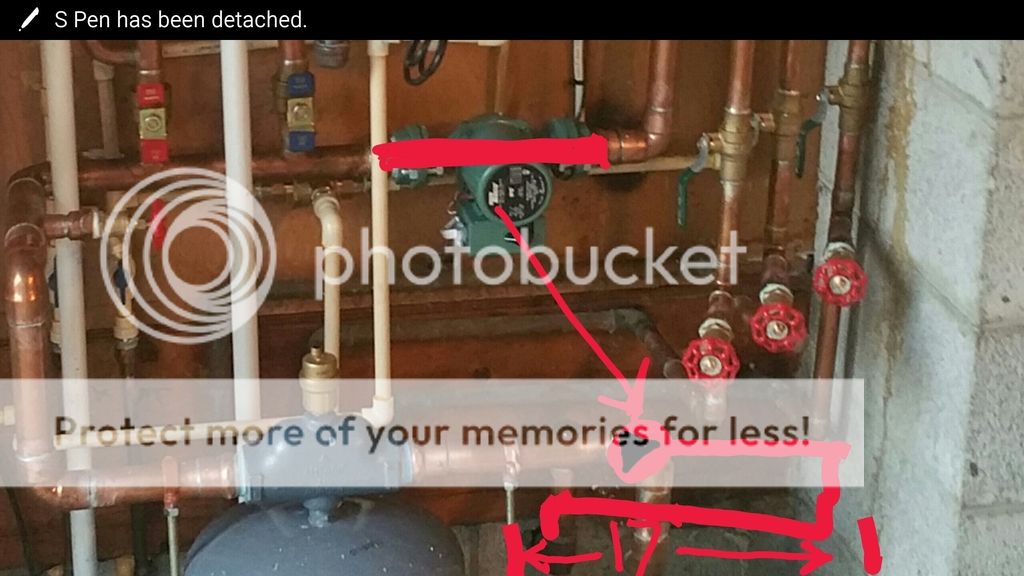

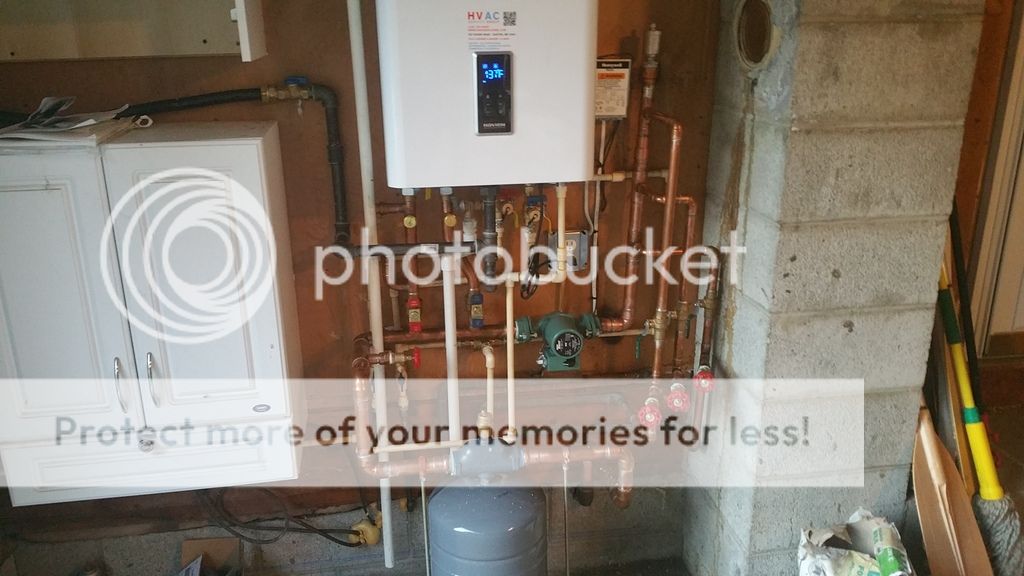

I just had a Navien NCB 240 boiler installed to replace an old Weil Mclain152k btu boiler that was leaking internally and I have some concerns:

First some back ground. After the 6 day long install (was quoted 8-10 hours by installers that I now realize aren’t worth anything) of redoing the plumbing until I was happy with it and thought it conformed to install requirements of the unit, the boiler has been up and running for 2 days now (heating working ok? DHW working on and off depending on current well pressure (another problem and long story)).

First problem is unit is running constantly for 18-20 h each day according to the thermostat (NEST). I cannot believe this is normal and cannot find much information on these online aside from this forum. I’m concerned what will happen when the temp drops to single digit numbers.

Burning Approx. 6 gallons of propane a day.

120 gal tank*.80%max fill = 96 gallons (moved 10 increments over the two days (0-80)) 96/80=1.2 gal per increment = 12 gal/2 days (just got off work please tell me if you see an error in that math)

Second is I think this unit can run much more efficiently then it currently is and am wondering if anyone can help with proper tuning numbers? Also I have seen a lot of mention of the outdoor temp sensor, would this help out significantly in my case?

I have only had about 20 min per day to watch the unit operate and I don’t think it is short cycling but I haven’t had time to remove the cover to watch the burner, just going by exhaust and sound.

Approx. low of 32 and high of 50 each day low to no wind

maintaining a constant 72 deg (I take care of a 94 year old man that demands this temp or higher) in a 1800 square foot house from 1959 with r13 in walls and ceiling , single pane windows

154’ of aluminum finned copper baseboard in a single zone configuration

With unit running:

Space heating supply water temp: 138-142

Space heating return water temp ~126

Space Heating water pressure 23.9 psi

Pump over run time 40 min

Burner off temp 4

Burner on temp 5

Supply absolute max 180

Supply absolute min 104

Return absolute max 149

Return absolute min 80

Thanks in advance for any advice.