Samat

Member

DanaShort-cycling is when there are many short burns per hour rather than fewer but longer burns. Ten or more burns per hour is a boiler-life shortening and efficiency robbing short-cycling disaster, under 5 burns/hour is fine, fewer than 3 is even better.

With high water volume cast iron it's almost never going to be a true short-cycling disaster, but it can often be improved quite a bit by dialing it in. And you probably have enough radiator to deliver nearly continuous burns, as outlined below. If you can drop from 25,000 ignition cycles per year to 5000 it'll do wonders for the longevity of the ignition components, and you will have saved the amount of heat blown out the venting by the 20,000 flue purges that were avoided.

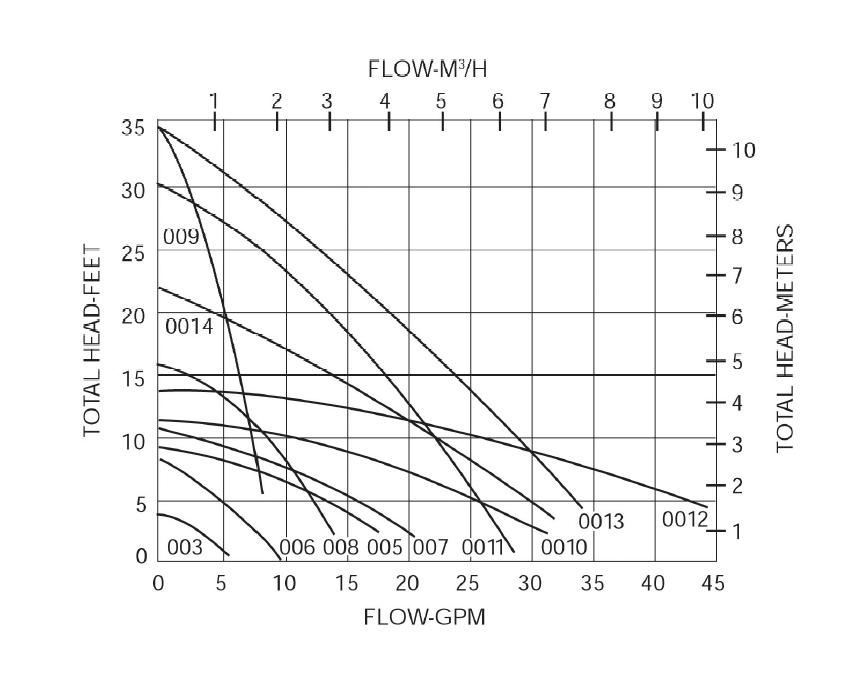

To get a handle on the output of the radiators you need to estimate the total "equivalent direct radiation" (EDR) of the zone. If you look at the nomograph in that sizing document you'll see that at an average water temp (AWT) of 120F (which is about what you get with an entering water temp or "EWT" of 125F from the boiler) you get about 50 BTU/hr out of the radiators, about a third of what you get at a AWT of 17oF (EWT of ~180F).

Assuming the flush mounted rads are 5" deep and 20" high they are likely either Arco SunRads or Burnham Radiants or one of the equivalents, which run about 1 square foot EDR for every inch of width, so you're looking at 350' EDR plus a little something for the radiant floor. At 125F they're putting out about 17,500 BTU/hr, which balances just fine with the minimum-fire output of the CH210, and should be delivering pretty much continuous burns. If you crank the water temp up to more than what's needed to cover the instantaneous heat loss from the building, the thermostat gets satisfied more quickly, but it results in more burns per hour/day/year. Any of these look familiar?

With an outdoor reset control if you dial it in super-finely you can get it to run many hours per burn, or even days, until the heat loss from the house is less than the boiler's minimum fire output. When it's dialed in that well you're in mod-con nirvana- the radiators are always warm, just warm enough and never scorching, the boiler is operating at it's maximum efficiency, and it's taking the least amount of wear & tear on the boiler. (BadgerBoilerMN, a frequent poster on this site, has a system that he operates ONLY with outdoor reset- it's hard-wired to always be calling for heat, no thermostat. With the curve dialed in he's always comfortable.)

Since you have a heating history on the place you can estimate the whole house heating load at any arbitrary outdoor temperature using this methodology, and from there work backward with your EDR number to figure out the water temperature needed to deliver the heat at your 99% outside design temp, and set it up close to ideal from the get-go rather than stumbling around in the dark taking stabs at different water temps and k-curves until it kinda-sorta works-mostly. For 180F operation assume the Navien operated at an efficiency of 87%, for making the fuel-use based load calculation.

The first picture is the radiators that are on the first zone. From what I understand I want to have this fire 24/7 for the best efficiency. At 125 at the present temps it's very close to doing that in zone one. I think as it gets colder since so far we have had a very warm January I may have play with the output temp. Looks like the big difference between the two zones will not allow me to do anything about the cycling differences between the two zones.

Once I've outside temps and inside boiler output figured I guess I could just change boiler temp as outside changes and deal only with zone one. The article you linked too is very interesting but I will need some time to digest it. I have a friend who is considering getting rid of his 30year old gas boiler and going to a mod-con. He is a physics teacher and would go crazy calculating.

My problem all along has been thinking that the navien needs to run like a old fashion boiler. Boy was I wrong but with help from you guys I'm really starting to understand things. Thanks a lot. With the CH is it worth for me to get the outdoor sensor?